EnzymoGenius™ Technology

- Home

- EnzymoGenius™ Technology

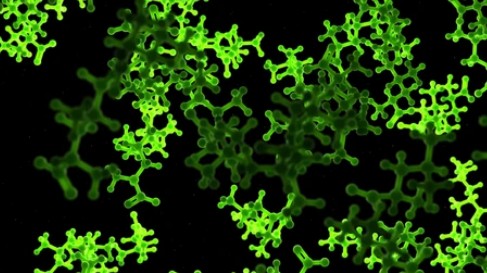

The EnzymoGenius™ Technology AI Enzyme Design and Evolution Platform is one of our core competencies. It aims to achieve targeted evolution and functional optimization of enzymes through advanced AI technology and high-throughput screening methods. The platform combines genetic engineering, machine learning and big data analysis to efficiently generate and screen enzyme variants with specific catalytic properties, thereby significantly improving enzyme activity, stability and catalytic efficiency.

"EnzymoGeniust lived up to its name by providing data-driven insights that bolstered my confidence in the predictions."

Alexa Young, CA

Through database mining and metagenome screening, we built a huge library of enzyme mutations, and used AI-assisted directed evolution technology to intelligently screen and optimize these enzymes.

In addition, our platform also integrates a variety of bioinformatics tools to predict the performance changes of enzymes under different conditions, and further improve the design accuracy and application effectiveness of enzymes through large-scale data analysis.

EnzymoGenius™ Technology is not only suitable for drug synthesis and biocatalysis, but can also be widely used in many fields such as industrial production and environmental protection, providing customers with efficient and accurate solutions and ensuring that the company maintains a leading position at the forefront of the industry.

The EnzymoGenius™ Technology AI enzyme design and evolution platform covers many aspects such as de novo design, directed evolution, optimization and transformation, and precise design using AI. These technologies jointly promote progress in the field of enzyme engineering.

AI-assisted enzyme engineering design

Use artificial intelligence technology to achieve standardization and accuracy of enzyme engineering design through high-quality data sets and deep learning models. This design method includes strategies such as rational design, directed evolution, semi-rational design and artificial intelligence-aided design

Designing artificial enzymes from scratch

Designing new enzymes from scratch using AI technology, introducing active sites and substrate binding pockets to catalyze the target chemical reaction. For example, a deep learning diffusion model is used to combine massive sequence data of P450 enzymes to design new functional P450 enzymes

Highly stable and powerful enzymes

Leverage complex computational design and deep learning algorithms to create new enzymes that can be used in real-world environments with higher temperature tolerance and longer working hours

Optimize and modify existing enzymes

AI algorithms can be used to optimize and modify known enzymes, such as the Cas9 enzyme, to find less toxic versions and assist in vector design and screening

Directed evolution of specific enzymes through a protein targeted modification and evolution platform to improve the catalytic activity, half-life, stability, heat resistance and interference resistance of the enzyme

Fluorescence-Activated Droplet Sorting (FADS) Technology

Fluorescence activated droplet sorting (FADS) is a microfluidics-based high-throughput screening technique used to isolate droplets that have functional functions. The procedure works much like flow cytometry (FACS), which detects and categorises target drops by observing fluorescent signals in the droplets.

PACE Technology: PACE technology

The strategy in which the phage acts as a vector for protein targeted evolution. By means of the phage display system, protein variants that have the right traits can be easily eliminated.

Microtiter Plate Screening (MTPS) technology

Microplate Screening (MTPS) technology is a widely adopted high throughput screening technique that tests the activity of a large number of compounds or samples by performing parallel experiments on a microplate. This technology utilizes automated liquid processing and reading devices that can be used to detect target compounds or reaction products.

Compartmentalized Self Replication (CSR) technology

Uterine self-replication (CSR) technology mimics the self-replication process in living systems and accomplishes self-replication by packaging crucial components, like DNA polymerase, into compartments.

Case1: Directed evolution to increase the catalytic efficiency of enzymes.

Project background:

A biopharmaceutical enterprise needs to enhance the catalytic activity of an essential enzyme so that they can develop drugs faster. It's a natural enzyme but its catalytic activity is not strong enough to support industrial production.

Solution:

Through the EnzymoGeniu™ Technology platform, along with directed evolution technology, a library of enzyme mutants is generated and screened using high-throughput screening and machine learning algorithms. Iteration upon iteration selects enzymes with greater catalytic performance.

Result:

Directed evolution takes several rounds, and the end enzyme version is 50% more catalytic than the original enzyme, drastically reducing the time required to develop a drug and reduce production costs.

TheEnzymoGeniu™Technology AI Enzyme Design and Evolution Platform offers vast potential in all industries. Here is a succinct overview of its primary uses:

Industrial production

Through directed evolution and rational design, enzymes can be made much more catalytically efficient and stable, encouraging the creation and use of new enzymes. Enzymes are used extensively in the industrial manufacturing of daily chemicals and useful substances. By evolving the AI design, enzyme catalytic reactions can be improved and production rates increased.

Biopharmaceuticals

Enzyme engineering technologies in the pharmaceutical industry can optimize enzyme activity via directed evolution and AI-driven design, increase the efficiency and purity of drug synthesis, and lower the cost of production.

Synthetic biology

Synthetic biology employs artificial intelligence to edit and create enzymes. It promotes synthetic biology by means of directed evolution, rational and semi-rational design techniques, which improve enzyme catalytic efficiency and substrate specificity.

Defense of the environment and sustainable development

Through AI-mediated enzyme molecular modification, effective catalytic biocatalysts can be created for environmental protection and sustainable development applications like biomass conversion.

Food processing

Enzymes are used in food processing to maintain food quality and keep it fresh. AI design evolution technologies yield novel, effective enzymes.

Agriculture

Use AI-generated enzymes to boost crop disease resistance and productivity and encourage sustainable agriculture.

Energies

Enhance biomass conversion rates and encourage the development of renewable energy with AI-guided enzyme design.

We're dedicated to providing our customers with unparalleled value through ourEnzymoGeniu™Technology AI Enzyme Design and Evolution Platform. - Our clients include some of the world's largest multinational pharmaceutical firms, biotechnology companies, etc.

We involve our customers fully in the entire process from needs definition to project execution to meet project objectives. We provide a personalized solution to customers ' special needs that improves their satisfaction and retention.

Using the powerfulEnzymoGeniu™Technology AI enzyme design and evolution technology platform, high-throughput screening and other technologies, we develop, modify and screen solutions to meet application requirements, build high-quality mutant libraries or perform large-scale protein library evaluation, and then manufacture Evolved enzymes with desired performance. Our vision is to be your best option and deliver superior services and products. Thanks for sharing with us how we can build together a better future.

Below are some of the most frequently asked questions customers may have and their solutions:

Q: What is theEnzymoGeniu™Technology AI Enzyme Design Evolution Platform?

A: EnzymoGeniusTM Technology is an AI enzyme design and evolution platform that achieves effective enzyme molecule design and optimization via smart algorithms and big data. This platform can generate and test millions of enzyme variants quickly, speeding up enzyme creation.

Q: So what are the key benefits of the EnzymoGenius TM Technology platform?

A: The main advantages include:

Q: What does the EnzymoGenius TM Technology solution offer to our customers?

A: The platform can help customers:

Q: For what purpose can the EnzymoGenius TM Technology platform be utilized?

A: The platform is useful in a variety of fields, including but not limited to:

Q: How to use the EnzymoGenius™ Technology platform?

A: The steps to use are as follows:

Q: What is the technical support and service guarantee of the EnzymoGenius ™ Technology platform?

A: We provide comprehensive technical support and service guarantees, including:

Q: How to use the EnzymoGenius™ Technology platform to design and transform enzymes?

A: The process of using this platform for enzyme design and transformation includes: first screening and evaluating a variety of enzymes existing in nature based on the application scenarios of the target enzyme; then selecting the appropriate wild-type enzyme as the female parent, and using randomization methods to generate a large number of protein libraries; finally obtaining sequence-structure-functional information of a large number of variants through a high-throughput screening scheme

Q: How to obtain services from the EnzymoGenius™ Technology platform?

A: You can directly contact our customer service department to provide your specific needs. We will customize detailed technical solutions and quotations for you, and sign a business contract after confirmation.

Q: How to calculate the service fee for the EnzymoGenius™ Technology platform?

A: Our fees are quoted separately based on the specific needs of the project and service content. Each service plan is quoted separately and delivered separately to ensure that customers can receive transparent and reasonable fees

Please take a moment to fill out the form.