01Overview

02Core Service Offerings

03Project Workflow

04Case Studies

05Application Areas

06Frequently Asked Questions (FAQs)

07Contact Us

Overview

Enzyme engineering has become more and more important for modern biotechnology.We provides outsourcing services of enzyme engineering. Our company is dedicated to offer professional engineering services that feature efficiency and innovation through advanced technology of enzyme engineering, in response to the needs for enzyme engineering of synthetic biology,medical and biomanufacture.Our leading position in this field was achieved by running our endeavour for years in deep technical accumulation and rich experience on many projects.

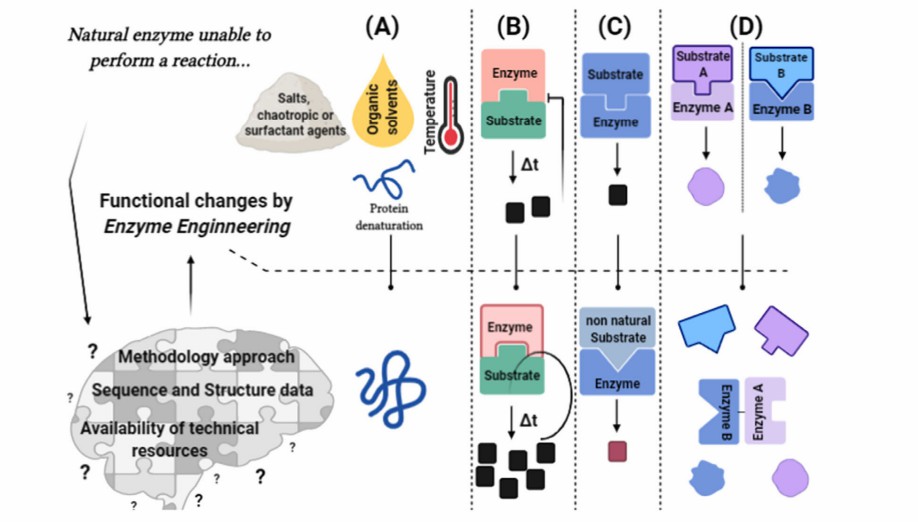

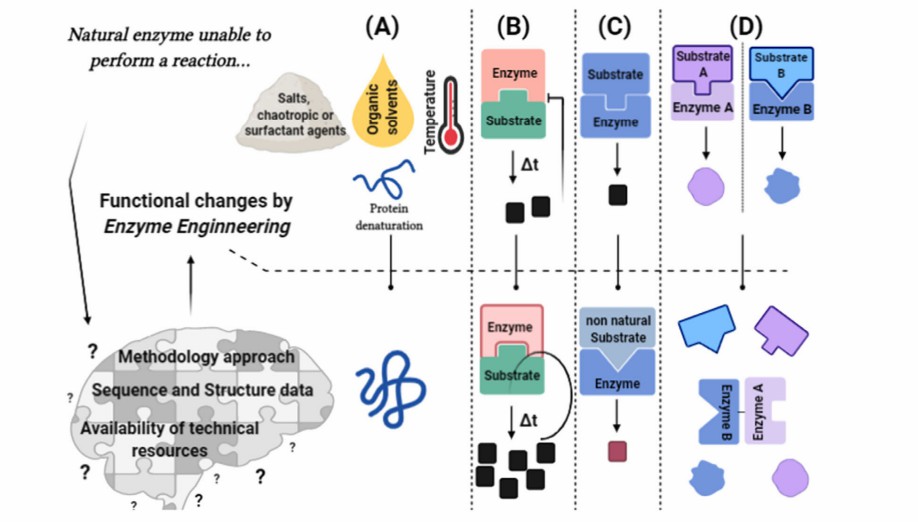

Enzyme Engineering (I Victorino da Silva Amatto, et al., 2012)

Enzyme Engineering (I Victorino da Silva Amatto, et al., 2012)

Enzyme engineering is one of the significant technologies, which utilizes the mimetic behaviours of enzyme as a catalyst and takes advantage of bench changes in conditions to induce chemcial reactions to obtain achieved products or service. We have a series of enzyme engineering service such as enzyme screening,expression optimization of protein,customized synthesis,enzyme function test and so on. As for the enzyme discovery and design,advanced bioinformatics and molecular modelling techs are also applied in our company to accelerate the new enzyme discovery and design to satisfy more and more the diverse needs of Industrial process.Our company tracks the market trends,feeds back more effectively,makes innovation to service mode,provides one-stop service covering the whole process of R&D earning chain for more customers which will accelerated the process of R&D,reduced the cost and raised the efficiency of R & D for them by achieving high quality service of enzyme engineering outsourcing.

Core Service Offerings

The Enzyme Engineering Services provided by our company mainly include the following aspects:

Better performance of enzymes in the desired way

make enzymes more suitable for a specific requirement in bioindustries or the environment by technical methods, ie, protein engineering to improve enzyme stability and activity.

01

Regulation of enzyme specificity and stereoselectivity

Introduction of point mutations in enzymes by protein engineering or other means to regulate their specificity and stereoselectivity to suit different requirements of chemical reactions.

02

Enzyme Immobile Technology

The enzyme immobile technology includes enzyme immobile technology and microbial cell immobile technology, as well as the function of enzyme traditional technology through immobile technology to stabilize the enzyme and the number of enzyme reuse.

03

Gene cloning and heterologous expression of enzymes

Using gene engineering and protein engineering, we are able to clone enzyme genes and express these in heterologous hosts, allowing us to produce enzymes for industrial use.

04

Chemical modification and molecular simulation of enzymes

chemical modification of the active center of enzymes; enzyme mimetics, including abzyme and molecular imprints; non-protein coding moieties (cofactors, nucleic acids, etc) to improve enzyme functions.

05

Development of enzyme application

develop and use enzyme engineering in food processing, pharmaceutical industry, environmental protection and other fields, e.g., development of functional foods, diagnosis of diseases and treatment and the decomposition and detoxification of pollutants.

06

Project Workflow

Enzyme Engineering Services The service process of this service:

Project start-up and needs analysis

Enzyme selection and optimization

Enzyme engineering design and transformation

Enzyme expression and purification

Characterization and verification of enzymes

Scale-up production and quality control

Technical documents and test reports

Customer support and follow-up services

- Project start-up and needs analysis:

The client expresses requirements in terms of enzyme engineering and provides more information about the project goals and exact needs.

We will discuss with the customer about necessary information and create an initial project plan.

- Enzyme selection and optimization:

Select the right enzyme or screen the enzyme according to customer needs.

Test enzyme expression, purification, and activity to ensure desired enzyme performance.

- Enzyme engineering design and transformation:

This enables the enzyme to become engineered to improve its catalytic efficiency, stability and selectivity.

Multiple mutants are constructed and screened to obtain the optimal enzyme variant.

- Enzyme expression and purification:

Use efficient methods to purify the enzyme to ensure high purity and activity of the enzyme.

- Characterization and verification of enzymes:

The enzyme was characterized in detail, including molecular weight, activity, stability, etc.

Test the enzyme to prove it can catalyse a reaction.

- Scale-up production and quality control:

Scale up laboratory-scale enzymes to industrial production scale.

- Technical documents and test reports:

Prepare a detailed report of the technical work undertaken by the enzyme engineering, such as the structure, activity, stability and other information about the enzyme.

- Customer support and follow-up services:

Provide technical support and consulting services to help customers solve problems encountered during use.

Continuously optimize enzyme performance and application plans based on customer feedback.

Through the following processes, we are delivering high-quality and efficient service of enzyme engineering to customers in different fields of research and development.

Case Studies

Case 1: Enzyme engineering to improve food processing efficiency

Project background:

A food processing company has a production problem because its machines work more inefficiently when processing fruits and vegetables. This is due to the fact that the traditional enzymes cannot work properly at high temperatures, which negatively affects product quality and raises production costs.

Solution:

We designed naturally produced enzymes that are more active at elevated temperature levels via engineering their structure and increasing the optimality of catalytic activity and thermal stability through 'directed evolution' by gene editing technology.

Result:

In the modified enzyme, the ability to process food has been improved, meaning that enzymes offer greater stability under processing conditions and, when reused, its activity is not significantly lost even after 30 production cycles. This means that they have a much longer period where they can be reused, saving the cost of producing enzymes. Moreover, the processing time for producing food has been shortened to 30 per cent, compared to the time before the use of engineered enzymes. This is beneficial as it decreases the duration of food production and allows for better food quality.

Case 2: Enzyme optimization in biofuel production

Project background:

A biofuel company wishes to increase the production and more specifics the potency of its biofuel. Currently, the efficiency of enzymes which help in processing of complex biomass raw materials such as wood or grass into digestible sugars is less. This results in overall production efficiency.

Solution:

By making use of new technology in directed evolution and genetic engineering transformation of existing enzymes, we have developed a new enzyme for efficiently converting complex biomass raw materials after multiple times of iterative screening and optimisation.

Result:

By modifying this enzyme, the number of reaction steps that convert the biomass raw materials went up by 40 per cent, increasing the amount of biofuel produced, and reducing production costs by 25 per cent – which is a significant economic benefit for the company.

Application Areas

The enzyme engineering services have got lots of fields of application and using ways across several industries and research routes. Our customers are working in the following areas:

01

Industrial applications:

- Biocatalysis and bioeconomy: enzyme engineering is a hot technology to promote biocatalysis and bioeconomy, which bolster up the synthesis of chemicals and materials from renewable resources in a clean sustainable way.

- Light chemical industry: the most important industrial fields currently use it in laundry detergent production, fur trading industry, gelatine manufacture, collagen fibre manufacture, toothpaste and cosmetics production, paper industry, photosensitive material production, wastewater and waste disposal, feed industry.

- Food processing: enzyme engineering can meet the requirements of certain application scenarios in food processing, including immobilised enzymes, rational design, semi-rational design, and directed evolution.

02

Pharmaceutical field:

- Drug research and development: New drug development from the industry needs enzyme engineering, original discovery, pharmacology, pharmacokinetics, safety toxicology, etc.

- Preclinical and Clinical Studies:Enzyme engineering can support preclinical and clinical studies, for instance in screening of compound activity, pharmacodynamic studies, safety studies etc.

03

Environmental monitoring and protection:

- Utilization of enzyme engineering in wastewater treatment would be in the following way. Enzyme engineering can ascertain the rational utilization of wastewater treatment by reducing odour emission and algae-growth and therefore can enhance the treatment efficiency. It also generates less waste sludge and contributes to reducing environmental pollution.

- Biosensors: The enzymes are used as biosensors for detecting and analysing pollutional substances and waste products in the environment.

Frequently Asked Questions (FAQs)

For those customers who are still unclear about the Enzyme Engineering Services our company provides, please refer to the following QAs:

Q: What is enzyme engineering?

A: Enzyme engineering, for example, seeks to optimise biocatalysts by improving or adding new functions, with applications in chemical synthesis and other biomedical fields. In the field of genomics, scientists have been working for decades to predict the consequences of mutating proteins, and to design new enzymes using computing technology.

Q: What are the main technical methods of enzyme engineering?

A: There are several technical methods related to enzyme engineering, including the methods of breaking and separation, purification and identification of the enzyme's activity; immobilisation and chemical modification technics; directed evolution and site-directed mutation. Commonly, enzyme engineering is mainly used to improve the stability of the enzyme, enzymatic activity and specificity.

Q: How are enzyme targeted modification services achieved?

A: However, enzyme targeted transformation services tend to rely on a combination of directed evolution technology and approaches called 'rational design'.

Q: In what fields does enzyme engineering have applications?

A: It promoted the development of targeted enzyme engineering, and was widely used in like medicine, food, light industry, chemical industry, environmental protection, energy, biological engineering etc. For example, enzymes could be used in the pharmaceutical for synthesis and biotransformation of drugs; In food fields, various enzymes were used for food processing and quality control.

Q: How to select the right enzyme for engineering?

A: The ability to pick a suitable enzyme will depend on the enzyme's catalytic activity, stability and substrate specificity. Suitable enzymes are identified by screening enzymes using gene clone libraries, or by screening the enzymes based on genomic DNA.

Q: What are the commonly used immobilization techniques in enzyme engineering?

A: The common strategies are shown in Figure below, including physical adsorption, covalent binding and cross-linking.The enzyme is able to be immobilised on the carrier and not lose its biological activity, thus achieving the effect of being re-used after one cycle.

Q: What is the directed evolution technology in enzyme engineering?

A: Directed evolution technology uses natural selection technology to evolve targeted proteins or nucleic acids in their development direction, and finally obtains a variety of enzymes that meet the requirement for production. It could increase catalytic activity and stability of the enzyme several times.

Q: What are the chemical modification techniques in enzyme engineering?

A: The chemical modification approaches involve the side chain modification (including carboxyl group, amino group, and mercaptan group), metal ion replacements, macromolecular binding, etc., that improve the enzyme stability and catalytic activities.

Q: What are the applications of enzyme engineering in industrial production?

A: Enzyme engineering is prevalent in industry now, for instance by using high-stability and high-activity lipases in decontamination industry, or using amylase for saccharification in the food industry.

Q: How to achieve efficient screening and optimization of enzymes?

A: Efficient screening and optimisation of enzymes generally require high-throughput screening technology together with the large-scale platforms of computational simulation. CSR platform provides high-throughput computational simulation of enzymes, through automation of the whole process of computational enzyme simulation.

If you would like to learn more about our services or have any cooperation needs, please feel free to contact us. We look forward to working with you to create success.

Enzyme Engineering (I Victorino da Silva Amatto, et al., 2012)

Enzyme Engineering (I Victorino da Silva Amatto, et al., 2012)