Enzyme Downstream Process Development is an advanced service that focuses on optimizing the steps that follow the completion of the enzymatic reaction. This process is an integral part of the purification and formulation of enzymes, playing a key role in a myriad of industrial applications. The significance of this process lies in the fact that it allows for the preservation of enzyme activity and the enhancement of recovery rates. By customizing this process, we can tailor the protocol to suit the unique characteristics of the enzyme in question, thereby increasing the overall productivity and efficiency of the operation.

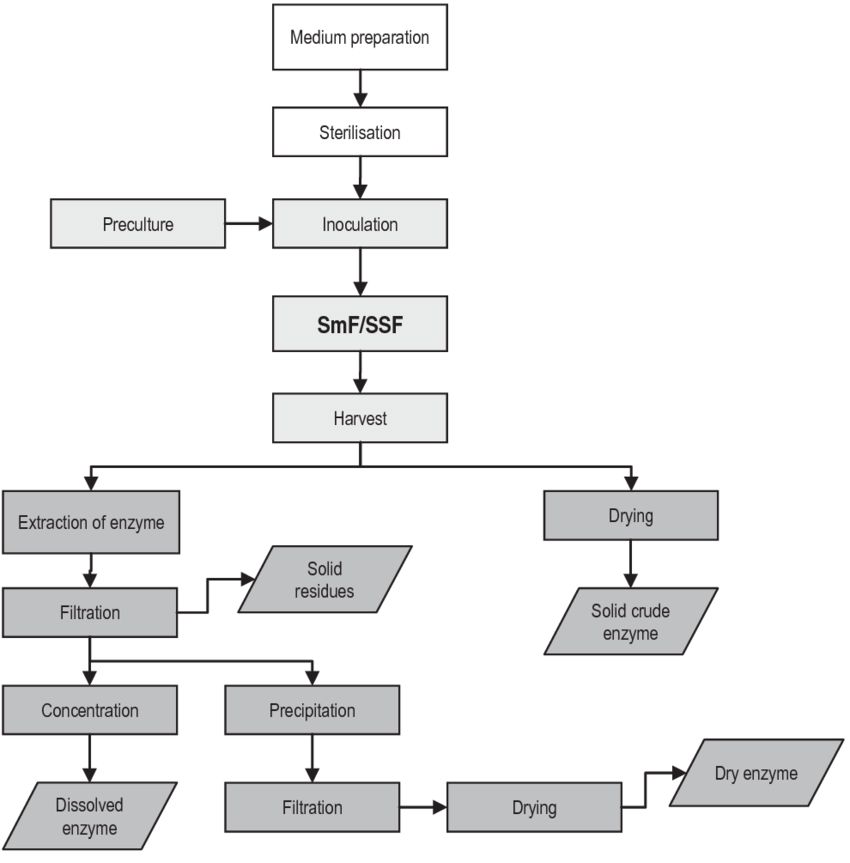

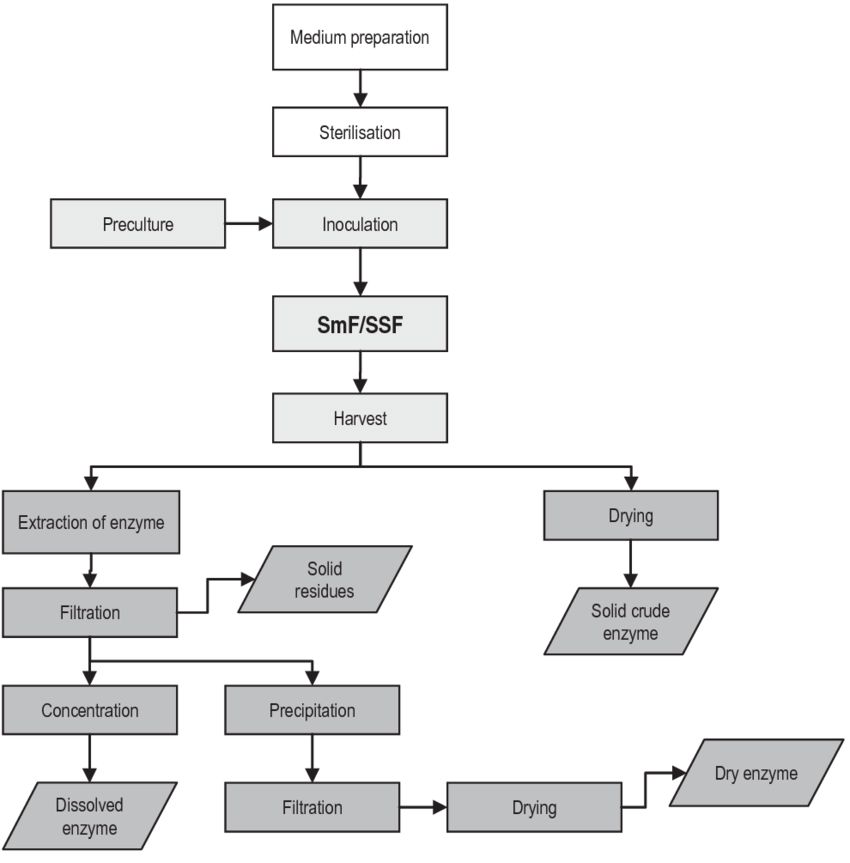

General flowchart of enzyme production: steps in downstream-processing in darker grey boxes (Martin Rühl, 2007)

General flowchart of enzyme production: steps in downstream-processing in darker grey boxes (Martin Rühl, 2007)

Service Process

Our Customize Enzyme Downstream Process Development service process involves several detailed steps:

- In-depth Consultation: We begin by conducting a thorough consultation to gain a comprehensive understanding of your specific needs and objectives. This involves detailed discussions with your team to understand the characteristics of the enzyme in question and your operational parameters.

- Customized Planning: Based on the insights gathered from the consultation, we develop a customized plan. This plan is tailored to align with your operational parameters, and it takes into account the unique characteristics of the specific enzyme.

- Plan Execution: Once the plan is finalized, we move on to its execution. This is an intricate process that is carried out meticulously by our experienced team. Each step of the process is executed carefully to ensure accuracy.

- Ongoing Monitoring: We don't just stop at execution. We conduct ongoing monitoring of the process to ensure that it is running optimally. Our team stays alert to any changes or potential issues that may arise during the process.

- Regular Adjustments: Based on the monitoring, regular adjustments are made as necessary. We understand that the process may need to be tweaked along the way for optimal results, and we are fully prepared to make these adjustments.

- Ensuring Desired Results: Our team is dedicated to ensuring that the process produces the desired results. We work persistently to ensure that the customized process is efficient and that it meets your specific objectives.

The aim of this thorough and detailed process is to ensure that our service is fully tailored to your needs and that it brings about an effective and efficient enzyme downstream process development. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Biopharmaceuticals |

Enzyme Downstream Process Development is critical in biopharmaceutical production for purifying enzymes to meet regulatory standards. It involves optimizing methods for protein isolation, purification, and formulation to ensure high product purity, stability, and activity. This process development is essential for manufacturing enzymes used in therapeutic drugs, diagnostic reagents, and biologics, ensuring consistent quality and safety for medical applications. |

| Food and Beverage Industry |

Enzyme Downstream Process Development finds application in the food and beverage industry for purifying enzymes used in food processing. It includes refining techniques for enzyme extraction, purification, and concentration to meet food-grade standards. This development ensures that enzymes employed in food applications, such as brewing, baking, and dairy processing, meet regulatory requirements and consumer expectations for safety, quality, and functionality, contributing to the efficient production of a wide range of food products. |

| Biofuel Production |

Enzyme Downstream Process Development is utilized in biofuel production to purify enzymes involved in biomass conversion processes. It involves optimizing methods for enzyme recovery, purification, and immobilization to improve efficiency and cost-effectiveness. This development ensures that enzymes used in lignocellulosic biofuel production, such as cellulases and hemicellulases, are efficiently recovered from fermentation broth, purified to high levels, and stabilized for repeated use, thereby enhancing the economic viability and sustainability of bioenergy technologies. |

| Waste Treatment |

Enzyme Downstream Process Development plays a role in waste treatment by purifying enzymes for biodegradation of organic pollutants. It includes optimizing methods for enzyme recovery and purification from microbial sources or engineered organisms. This development ensures the availability of highly active and stable enzymes for applications in wastewater treatment, bioremediation, and organic waste recycling, facilitating the efficient degradation of pollutants and the sustainable management of environmental resources. |

| Industrial Enzyme Markets |

Enzyme Downstream Process Development is crucial in industrial enzyme markets for purifying enzymes used in various applications. It involves refining purification techniques to meet specific industry requirements, such as textile processing, pulp and paper production, and detergent manufacturing. This development ensures that enzymes meet quality standards, performance criteria, and cost targets, enabling their widespread adoption in industrial processes for enhancing efficiency, sustainability, and product quality across diverse sectors. |

FAQs

Here are some frequently asked questions (FAQs) about Enzyme Downstream Process Development, including aspects like its purpose, importance, application across industries, cost implications, and how you can engage our services. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: Can you elaborate on what exactly Enzyme Downstream Process Development entails?

A: Enzyme Downstream Process Development constitutes a critical phase in enzyme processing. This process involves the steps that occur post the enzymatic reaction. The primary focus here is on the purification and formulation of enzymes, both of which are vital for their subsequent utilization in a variety of applications across numerous industries.

Q: Why is the customization of this process considered important?

A: Customization is not just important, but vital to ensure that the process aligns with the specific characteristics of the enzyme and the application it is intended for. By tailoring the process, we can ensure optimal preservation of enzyme activity and improved recovery rates, which ultimately leads to a significant boost in productivity and efficiency.

Q: Could you specify which industries are able to leverage this service?

A: Enzyme Downstream Process Development is not limited to a single industry. Any industry that relies on enzymatic processes can take advantage of this service. This includes, but is not limited to, the pharmaceutical industry, biofuel production, the food industry, and many other industries that utilise enzymatic processes in their operations.

Q: Is the customization process often expensive?

A: While it is true that there may be an upfront cost associated with the customization of the process, it's important to consider the bigger picture. The resultant increase in productivity and efficiency can offset these initial expenses, making it a worthwhile investment in the long run.

Q: What is the typical timeline to develop a customized process?

A: The development timeline can vary greatly, largely dependent on the complexity of the enzymatic process and the desired outcomes. However, our team is dedicated to delivering the most effective solution in the shortest possible time frame.

Q: Does your team have the capability to handle all types of enzymes?

A: Absolutely. Our team boasts extensive experience with a wide variety of enzymes. This expertise equips us to customize the process to suit any type of enzyme, regardless of its specific characteristics or intended application.

Q: Do you provide support after the development process has been completed?

A: Yes, we certainly do. We offer ongoing support to ensure that the process continues to meet your needs and is adaptable to any changes in your operational parameters. Our commitment to your success extends well beyond the initial development process.

Q: Could you provide some examples of potential applications of the developed process?

A: The applications of Enzyme Downstream Process Development are remarkably diverse, spanning across different sectors. This can range from drug development in the pharmaceutical industry, to biofuel production, food processing, and many more.

Q: How can I engage your services?

A: Engaging our services is straightforward. To get started, you can contact us directly to discuss your specific needs. We are committed to providing you with the best possible solution, tailored to your unique circumstances and objectives.

General flowchart of enzyme production: steps in downstream-processing in darker grey boxes (Martin Rühl, 2007)

General flowchart of enzyme production: steps in downstream-processing in darker grey boxes (Martin Rühl, 2007)