Enzyme Design for Chiral Synthesis is a cutting-edge technology that harnesses the power of enzymes, nature's own catalysts, to facilitate the synthesis of chiral compounds. These special molecules have a "left-handed" and a "right-handed" form, each potentially having different effects in biological systems. This technology is crucial in new drug development, as the correct chiral form often leads to beneficial therapeutic effects, while the opposite form could result in harmful side effects. Utilizing this technology allows us to contribute to the production of safer, more effective medications.

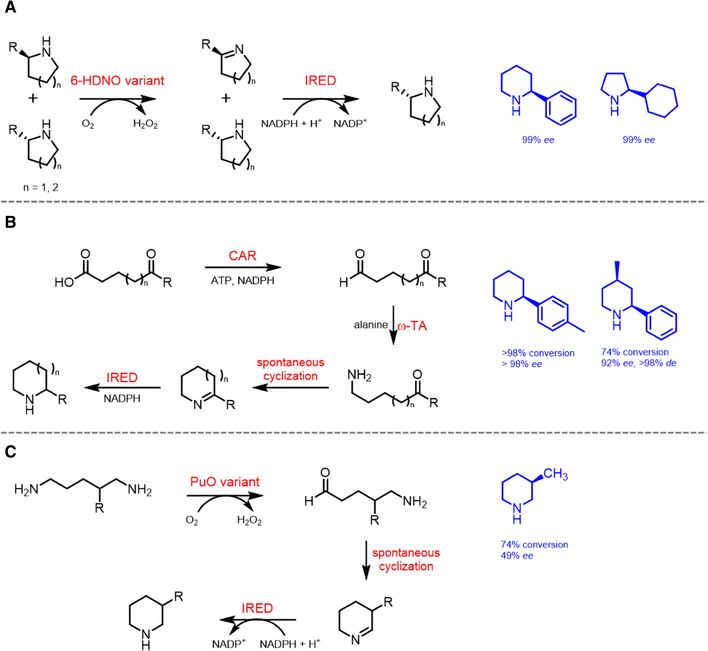

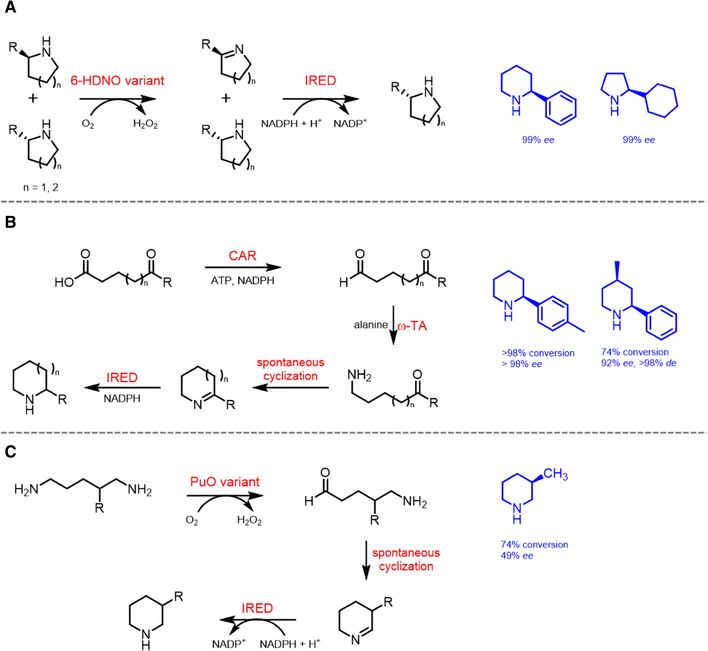

Overview of enzymatic cascades for the synthesis of chiral substituted piperidines and pyrrolidines heterocycles through a deracemization of chiral amines (Maike Lenz, 2017)

Overview of enzymatic cascades for the synthesis of chiral substituted piperidines and pyrrolidines heterocycles through a deracemization of chiral amines (Maike Lenz, 2017)

Service Process

Our service process has been meticulously designed to be both comprehensive in scope and focused on the needs of our clients. It encompasses a series of carefully planned and executed steps:

- Initial Consultation: We start with a thorough consultation where we discuss your specific needs. This conversation allows us to understand the unique requirements and goals for your project.

- Definition of Project Scope: Based on the initial consultation, we define the scope of the project. This includes finalizing the details of the desired enzyme and the specific reaction it should catalyze.

- Enzyme Design: Once we have a clear understanding of the project's requirements, we move on to the design stage. Here, we utilize advanced in silico methods to design the enzyme that will fulfil your project's needs.

- Validation of Enzyme Design: The design of the enzyme is then validated using computational models. This step ensures that the enzyme is predicted to function as intended before we proceed to the experimental phase.

- Laboratory Testing: After computational validation, the enzyme undergoes rigorous lab testing. This process allows us to confirm the performance and reliability of the enzyme in a controlled environment.

- Fine-Tuning: Based on the results from lab testing, we make any necessary adjustments to the enzyme design. This fine-tuning process ensures that the enzyme will perform optimally in its intended application.

- Delivery of the Enzyme: Once testing and fine-tuning are complete, the enzyme is ready to be delivered. We ensure a smooth handover process so you can begin using the enzyme in your work right away.

- Follow-Up Support: Our service doesn't end after the enzyme delivery. We believe it's essential to provide follow-up support to ensure the enzyme meets your expectations and to address any questions or concerns you may have.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Pharmaceutical Industry |

Enzyme design for chiral synthesis finds extensive application in the pharmaceutical industry. Enzymes are engineered to catalyze specific reactions with high stereoselectivity, enabling the production of chiral pharmaceutical compounds in an efficient and environmentally friendly manner. This approach helps in the synthesis of enantiopure drugs, which are often more effective and safer than racemic mixtures. |

| Chemical Manufacturing |

Enzyme design for chiral synthesis is utilized in chemical manufacturing processes to produce optically pure compounds. Enzymes are engineered to catalyze reactions selectively, yielding chiral molecules with desired stereochemistry. This application offers advantages such as high yields, mild reaction conditions, and reduced waste generation compared to traditional chemical methods. Enzymatic chiral synthesis is particularly valuable in the production of fine chemicals, agrochemicals, and specialty compounds where stereochemical purity is crucial for product efficacy and market acceptance. |

| Food and Beverage Industry |

Enzyme design for chiral synthesis plays a role in the food and beverage industry, particularly in the production of flavor and fragrance compounds. By engineering enzymes with desired stereoselectivity, manufacturers can produce chiral molecules that contribute to the unique tastes and aromas of various food and beverage products. |

| Biotechnology |

Enzyme design for chiral synthesis has applications in biotechnology, including the production of enantiopure intermediates for the synthesis of pharmaceuticals, biofuels, and other bioproducts. Engineered enzymes enable the selective transformation of substrates into chiral molecules, facilitating the development of sustainable and renewable processes in biomanufacturing. |

| Environmental Remediation |

Enzyme design for chiral synthesis finds emerging applications in environmental remediation, particularly in the degradation of chiral pollutants and xenobiotics. Engineered enzymes capable of metabolizing specific enantiomers of environmental contaminants offer a promising approach for bioremediation efforts. By selectively targeting harmful chiral compounds, these enzymes facilitate the detoxification and removal of pollutants from soil, water, and air, contributing to environmental sustainability and ecosystem health. |

Case Study

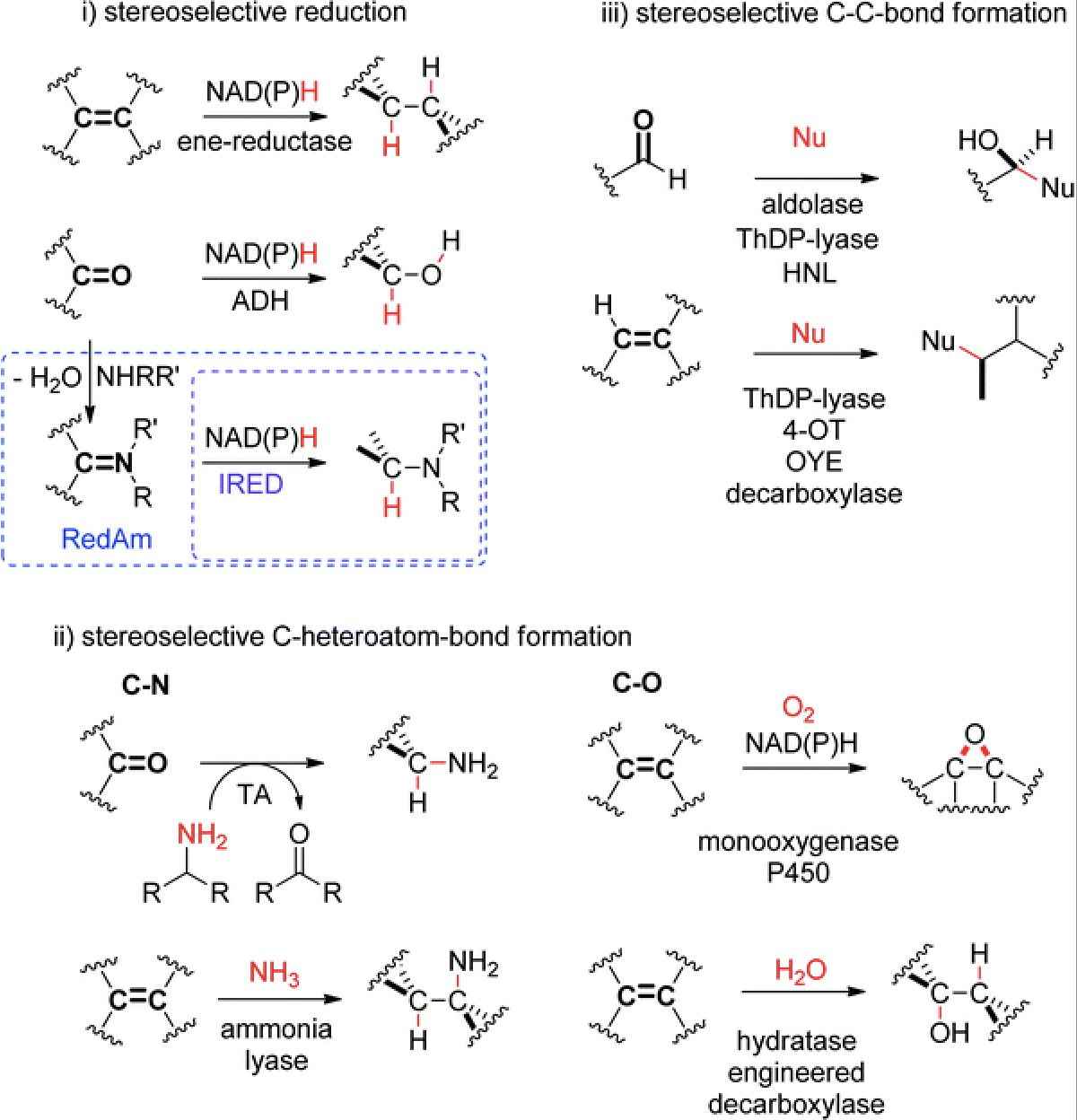

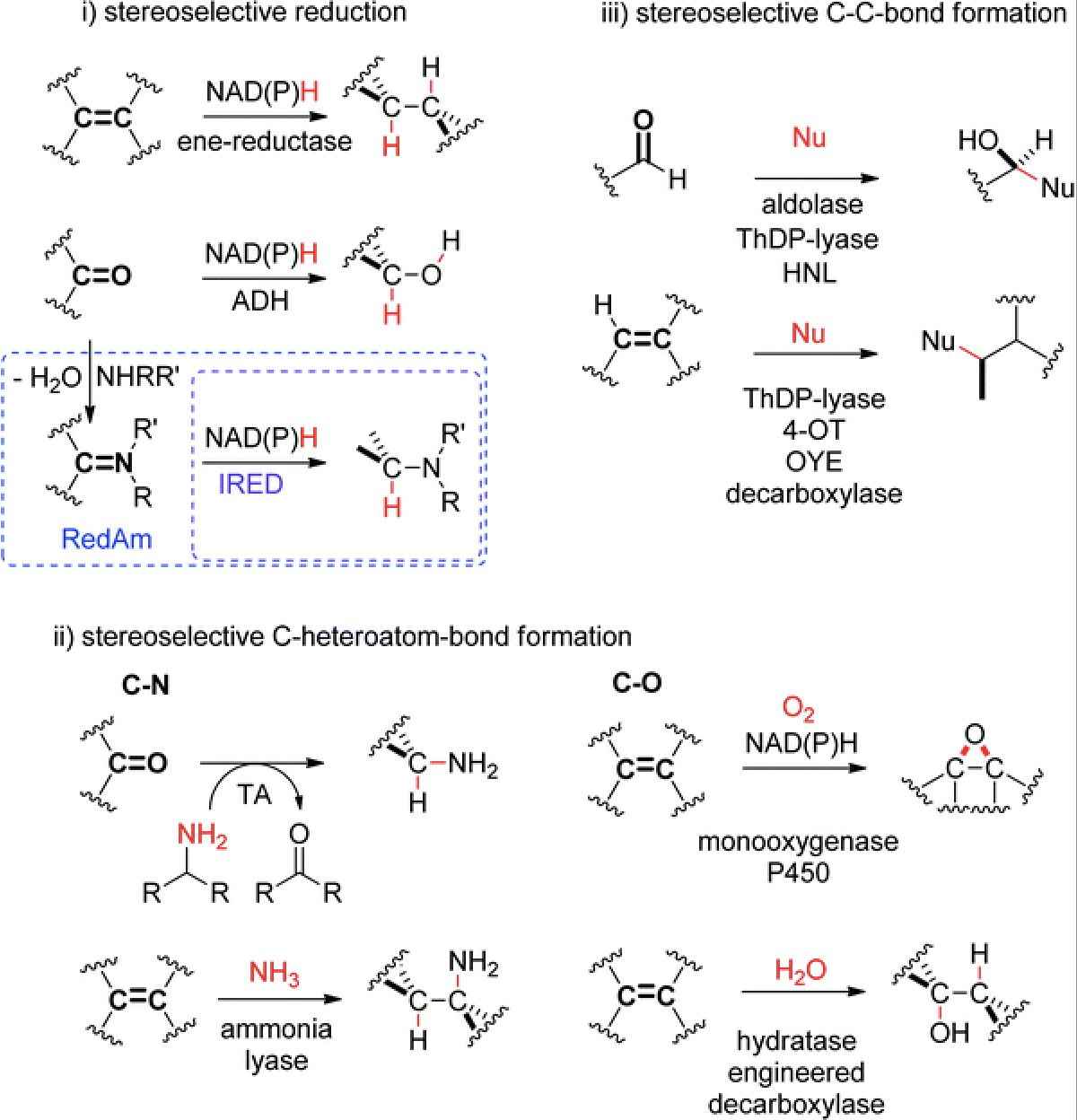

The biocatalytic stereoselective conversion of prochiral molecules into chiral products often involves substrates bearing at least one sp2 hybridized carbon atom embedded in a double bond, such as C[double bond, length as m-dash]C-, C[double bond, length as m-dash]N- or C[double bond, length as m-dash]O-bond. Transformations of these double bonds include reduction reactions (stereoselective C–H bond formation), transamination and hydroamination (stereoselective C–N-bond formation), epoxidation (stereoselective C–O-bond formation), and addition of nucleophilic carbon (stereoselective C–C-bond formation). All these reactions proceed through selective substrate face recognition by the enzyme of interest and may lead to the formation of up to two chiral centers. The figure below shows that the enzymatic asymmetric strategy relies on stereoselective reactions. (i) reduction, (ii) C–heteroatom-bond formation and (iii) C–C-bond formation by addition of nucleophilic carbon (4-OT: 4-oxalocrotonate tautomerase, ADH: alcohol dehydrogenase, HNL: hydroxynitrile lyase, IRED: imine reductase, OYE: Old Yellow Enzyme, RedAm: reductive aminase, TA: transaminase, ThDP: thiamine diphosphate, Nu: nucleophile).

Enzymatic strategies for asymmetric synthesis (Mélanie Hall, 2021)

Enzymatic strategies for asymmetric synthesis (Mélanie Hall, 2021)

FAQs

Here are some frequently asked questions about chiral synthesis and enzyme design, along with their answers to provide a better understanding of the process, its benefits, challenges, and other key aspects. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: What is the concept of chiral synthesis?

A: Chiral synthesis is a process of specific precision, wherein a particular chiral form of a compound is selectively created. This can be either a left-handed (levo) or right-handed (dextro) form. This concept is of paramount importance within the pharmaceutical industry as the different chiral forms can exhibit different effects upon the human body, sometimes drastically so. The correct chiral form can lead to the anticipated therapeutic effects of a drug, while the other may be inactive or, in some cases, cause adverse effects.

Q: Why is the use of enzymes recommended in chiral synthesis?

A: Enzymes, often referred to as nature's own catalysts, provide an efficient method to accelerate chemical reactions while ensuring a high degree of selectivity. This makes them optimal tools for chiral synthesis, as they allow for tight control over the production of the desired chiral form of a compound. Enzymes are highly specific, often catalyzing only one reaction in one particular type of molecule (substrate). This specificity can ensure the production of one enantiomer over the other.

Q: What is the process of enzyme design? How is it achieved?

A: Enzyme design is a sophisticated process that employs cutting-edge computational tools. These tools enable us to design enzymes that can catalyze specific reactions, thereby making the process of chiral synthesis more effective, predictable, and controllable. The process involves predicting the three-dimensional structure of the protein, studying the active site, and making modifications to improve its activity or specificity.

Q: Are there any benefits to using enzyme design for chiral synthesis? If so, what are they?

A: Indeed, enzyme design for chiral synthesis provides a plethora of benefits. Firstly, it is an efficient and selective method that allows for the precise control over the synthesis process. This precision helps in the production of a specific chiral form of a compound, which can be crucial in drug development. Secondly, it's an environmentally friendly approach, as it significantly reduces the need for harsh chemicals and excessive energy usage, contributing to sustainable and green chemistry. Lastly, enzyme-catalyzed reactions often occur under mild conditions and are capable of producing high yields, reducing the costs associated with traditional synthetic methods.

Q: What is the importance of chiral compounds in the pharmaceutical industry?

A: Chiral compounds play a crucial role in the pharmaceutical industry. The two enantiomers of a chiral drug molecule often exhibit different biological activities. One enantiomer can have therapeutic effects, while the other may be inactive or even harmful. Therefore, the ability to selectively synthesize one enantiomer of the drug molecule can greatly increase the safety and efficacy of the drug.

Q: What are the challenges in enzyme design for chiral synthesis?

A: While enzyme design for chiral synthesis offers numerous advantages, it also presents a few challenges. These include the complexity of protein structures, the lack of complete understanding of enzyme catalysis at the molecular level, and the limitations of computational tools. However, continuous advancements in computational biology and protein engineering are helping to overcome these challenges.

Q: How long does the enzyme design process typically take?

A: The duration of the enzyme design process can vary greatly depending on the complexity of the desired reaction and the specifics of the project. It can range from a few weeks to several months.

Q: Are there any risks associated with using enzymes in chiral synthesis?

A: While enzymes are generally safe and environmentally friendly, there can be risks if they're not used properly. These risks can be mitigated through careful design and rigorous testing.

Q: Can any enzyme be used for chiral synthesis?

A: Not all enzymes are suitable for chiral synthesis. The chosen enzyme must have the appropriate structure and properties to catalyze the desired reaction.

Q: How do you ensure the quality and effectiveness of the designed enzyme?

A: We validate the enzyme design using computational models and conduct rigorous lab testing to confirm its performance and reliability.

Q: Can you customize the enzyme design process to meet specific project needs?

A: Yes, our enzyme design process is flexible and can be tailored to meet the specific needs of each project.

Overview of enzymatic cascades for the synthesis of chiral substituted piperidines and pyrrolidines heterocycles through a deracemization of chiral amines (Maike Lenz, 2017)

Overview of enzymatic cascades for the synthesis of chiral substituted piperidines and pyrrolidines heterocycles through a deracemization of chiral amines (Maike Lenz, 2017) Enzymatic strategies for asymmetric synthesis (Mélanie Hall, 2021)

Enzymatic strategies for asymmetric synthesis (Mélanie Hall, 2021)