Enzyme stabilization via immobilization is a process where enzymes are physically attached or bound to a stable, inert matrix like a gel or microbead. This process significantly improves the enzymes' stability and efficiency, making them more resilient to environmental changes like temperature and pH levels. This is especially advantageous for enzyme gene and plasmid synthesis as it enhances reaction control and prolongs the enzyme's lifespan. As a result, the enzyme can be reused repeatedly without loss of activity, leading to cost savings and heightened productivity.

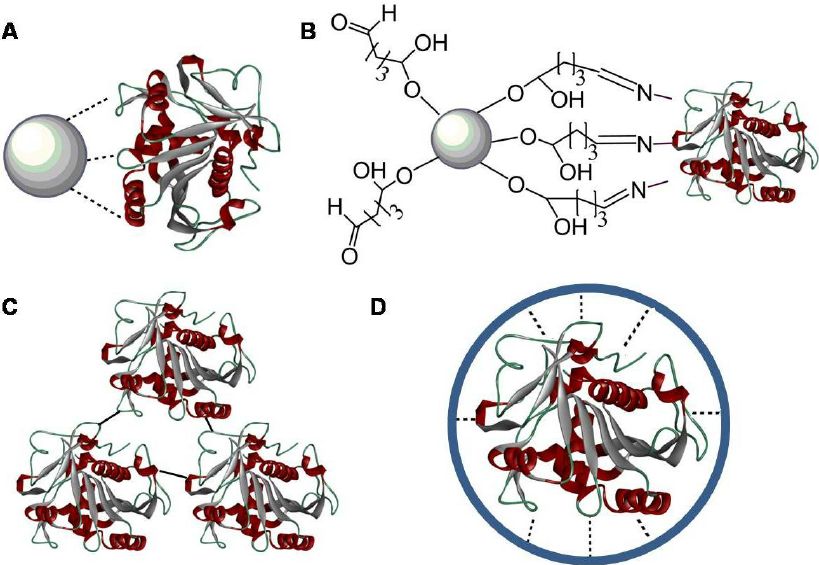

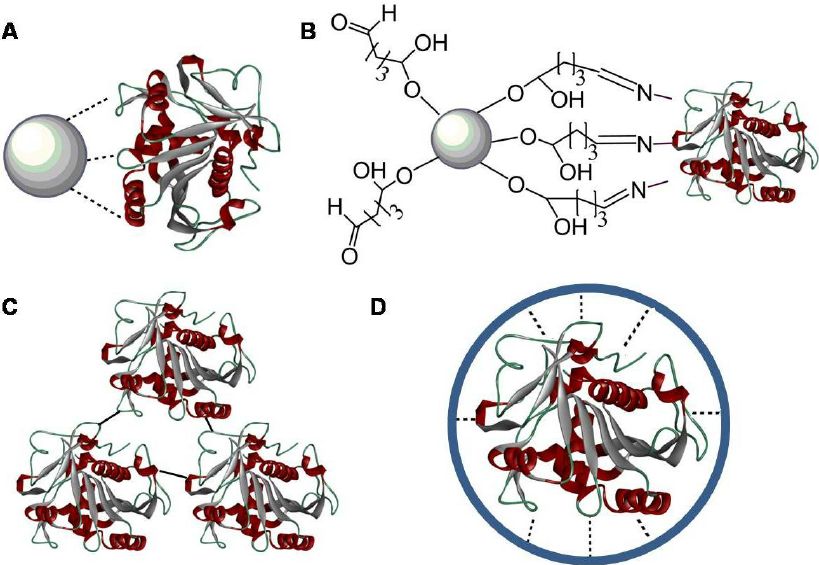

Enzyme stabilization by immobilization introduces additional covalent and non-covalent forces to an external matrix (Raushan Kumar Singh, et al., 2013)

Enzyme stabilization by immobilization introduces additional covalent and non-covalent forces to an external matrix (Raushan Kumar Singh, et al., 2013)

Service Process

Our Enzyme Stabilization by Immobilization service is designed to deliver exceptional results. We utilize a meticulous and thorough process to ensure top quality, performance, and customer satisfaction:

- Initial Consultation: Our service begins with a detailed understanding of your specific requirements and the application for which the enzyme will be used. This allows us to cater our services to your specific needs, ensuring your project's success.

- Customized Project Proposal: Following the initial consultation, we prepare a meticulously tailored project plan. This plan includes details on the method of immobilization that we will use, a timeline for the project, and a comprehensive breakdown of the cost involved.

- Enzyme Immobilization Process: Once the project plan is agreed upon, the next step is the actual immobilization of the enzyme. This critical phase is carried out under carefully controlled conditions to ensure the enzyme retains optimal activity and stability.

- Rigorous Quality Assurance: After the enzyme has been immobilized, our team undertakes a thorough testing and validation process. We ensure that the immobilized enzyme meets the required specifications and the highest quality standards.

- Delivery of the Final Product: Finally, the immobilized enzyme is prepared for delivery. We package it as per your requirements and ensure it arrives at your desired location in perfect condition, ready for use in your application.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Biotechnology |

Enzyme Recombinant Expression Vector Construction plays a vital role in biotechnology by enabling the production of recombinant enzymes in host organisms for various applications. This process involves the design and construction of expression vectors containing the genes encoding target enzymes, along with regulatory elements such as promoters, signal peptides, and selection markers. These vectors facilitate the efficient expression and secretion of enzymes in host cells, allowing for their large-scale production and utilization in biotechnological processes, including industrial biocatalysis, pharmaceutical production, and metabolic engineering. |

| Pharmaceutical Research |

Enzyme Recombinant Expression Vector Construction is essential in pharmaceutical research for the production of therapeutic proteins, enzymes, and antibodies. Expression vectors are designed to efficiently express target genes in host cells, allowing for the production of recombinant proteins for drug discovery, development, and biopharmaceutical manufacturing. These vectors enable the high-yield expression of bioactive molecules, facilitating research into novel drug candidates, disease mechanisms, and therapeutic interventions. |

| Agricultural Biotechnology |

In agricultural biotechnology, Enzyme Recombinant Expression Vector Construction is employed for the development of genetically modified crops with improved traits, such as enhanced resistance to pests, diseases, and environmental stresses. Expression vectors are used to introduce genes encoding beneficial enzymes or proteins into plant genomes, enabling the expression of desired traits for increased yield, quality, and sustainability in agriculture. These vectors facilitate the genetic engineering of crops for traits such as enhanced nutrient uptake, drought tolerance, and pest resistance, contributing to global food security and agricultural sustainability. |

| Environmental Bioremediation |

Enzyme Recombinant Expression Vector Construction plays a role in environmental bioremediation by facilitating the production of recombinant enzymes for the degradation and detoxification of environmental pollutants. Expression vectors are designed to express genes encoding enzymes capable of breaking down contaminants such as hydrocarbons, pesticides, and industrial chemicals. These vectors enable the deployment of engineered microorganisms or enzyme formulations for bioremediation applications, contributing to the cleanup and restoration of contaminated soil, water, and air environments. |

| Industrial Fermentation Processes |

In industrial fermentation processes, Enzyme Recombinant Expression Vector Construction is employed for the production of enzymes and proteins used as biocatalysts in bioprocesses such as fermentation, biofuel production, and biochemical synthesis. Expression vectors are designed to express genes encoding enzymes with desired properties, including high activity, stability, and substrate specificity. These vectors enable the large-scale production of recombinant enzymes in microbial hosts such as bacteria, yeast, or fungi, facilitating the optimization and efficiency of industrial bioprocesses for the production of biofuels, pharmaceuticals, and biochemicals. |

Case Study

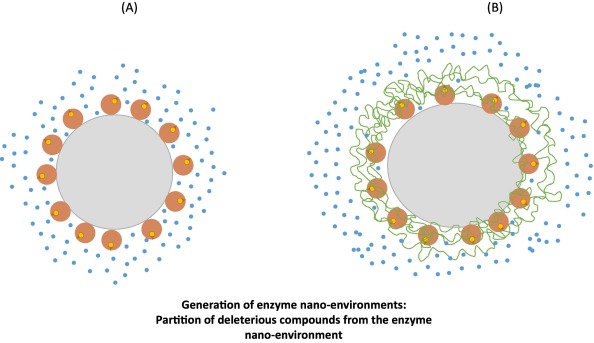

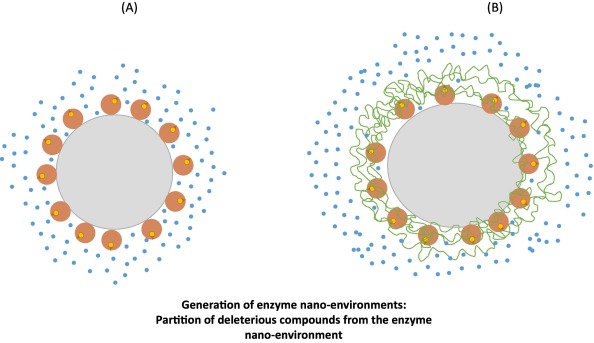

Enzyme immobilization enhances stability by isolating harmful compounds from the enzyme's surroundings, thus mitigating inactivation risks. Typically, this method creates a hydrophilic environment post-immobilization. In the illustration below, an enzyme is immobilized on a support coated with a hydrophilic polymer, potentially preventing or reducing deactivation by hydrophobic substrates at high concentrations. This protection may stem from interactions with different enzyme surface regions (e.g., catechol or phenol), hydrophobic solvents, or oxygen-induced enzyme deactivation.

Enzyme stabilization by just preventing enzyme exposition to some inactivation causes (Rafael C. Rodrigues, et al., 2021)

Enzyme stabilization by just preventing enzyme exposition to some inactivation causes (Rafael C. Rodrigues, et al., 2021)

FAQs

Here is a collection of frequently asked questions regarding our enzyme stabilization via immobilization services, which provide insights into the process, its benefits, and how it can be utilized in various sectors. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: Can you elaborate on what types of enzymes can be immobilized?

A: Essentially, there is a broad range of enzymes that can be immobilized, the specific type largely depends on the intended application. This includes, but is not limited to, enzymes used for industrial biotechnology, pharmaceutical production, and processing in the food and beverage industry, among others.

Q: Does the process of immobilization have any effect on the activity of the enzyme?

A: It is important to note that while immobilization can potentially affect the activity of the enzyme, our process is specifically designed and meticulously crafted to minimize this impact. We utilize carefully optimized immobilization techniques with the primary goal of ensuring that the enzyme retains its maximum activity.

Q: Could you explain how the process of enzyme immobilization is performed?

A: The process of enzyme immobilization is performed by attaching the enzyme to an inert, stable matrix. This procedure is carried out using a variety of methods such as covalent bonding, adsorption, and entrapment, with the choice of method depending on the specific requirements of the application.

Q: Why is the stabilization of enzymes necessary?

A: Enzyme stabilization is of utmost importance as it enhances the enzyme's resistance to changes in conditions such as pH and temperature, which in turn increases its longevity and control over the reaction. This allows the enzyme to be used in a wider range of conditions and for longer periods, thereby increasing efficiency and reducing costs.

Q: How does the process of immobilization impact the efficiency of the enzyme?

A: Immobilization significantly enhances enzyme efficiency by increasing stability and resistance to environmental changes. This means that the enzyme can maintain its activity even under adverse conditions, leading to improved reliability and performance.

Q: Are immobilized enzymes reusable?

A: Indeed, one of the main advantages of immobilization is that the enzymes can be reused. This not only reduces costs but also significantly reduces waste, making the process more environmentally friendly.

Q: Could you provide some examples of applications that can benefit from enzyme immobilization?

A: Enzyme immobilization is beneficial in a wide variety of sectors, including but not limited to pharmaceuticals, biofuels, the food and beverage industry, and more. It allows for increased productivity, cost savings, and improved environmental performance.

Q: How does immobilization contribute to gene and plasmid synthesis?

A: Immobilization plays a crucial role in gene and plasmid synthesis by increasing the longevity of the enzyme and improving control over the reaction. This results in more precise and reliable synthesis, making it an invaluable tool in biotechnology.

Q: What would be the procedure to avail this service from your company?

A: To avail of our enzyme immobilization services, please feel free to contact us directly. We would be more than happy to provide you with more information, discuss potential cooperation opportunities, and guide you through our processes.

Enzyme stabilization by immobilization introduces additional covalent and non-covalent forces to an external matrix (Raushan Kumar Singh, et al., 2013)

Enzyme stabilization by immobilization introduces additional covalent and non-covalent forces to an external matrix (Raushan Kumar Singh, et al., 2013) Enzyme stabilization by just preventing enzyme exposition to some inactivation causes (Rafael C. Rodrigues, et al., 2021)

Enzyme stabilization by just preventing enzyme exposition to some inactivation causes (Rafael C. Rodrigues, et al., 2021)