01Overview

02Core Service Offerings

03Project Workflow

04Case Studies

05Application Areas

06Frequently Asked Questions (FAQs)

07Contact Us

Overview

CD Biosynsis focuses on custom enzyme production for customers. We offer custom enzyme production services which involve all steps from enzyme design and synthesis to optimization and scale-up production so that customers get the best, pure enzyme products.

We do not just produce enzymes, but also maintain and optimize enzyme preparations for different customers' requirements. Either feed additives or industrial uses, we offer custom enzymes to help customers get the most value.

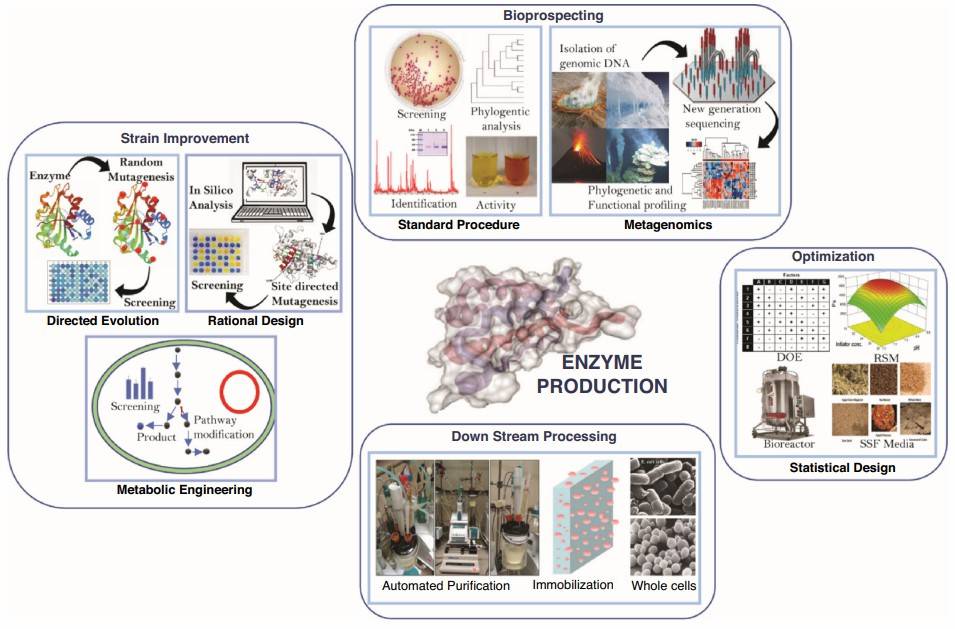

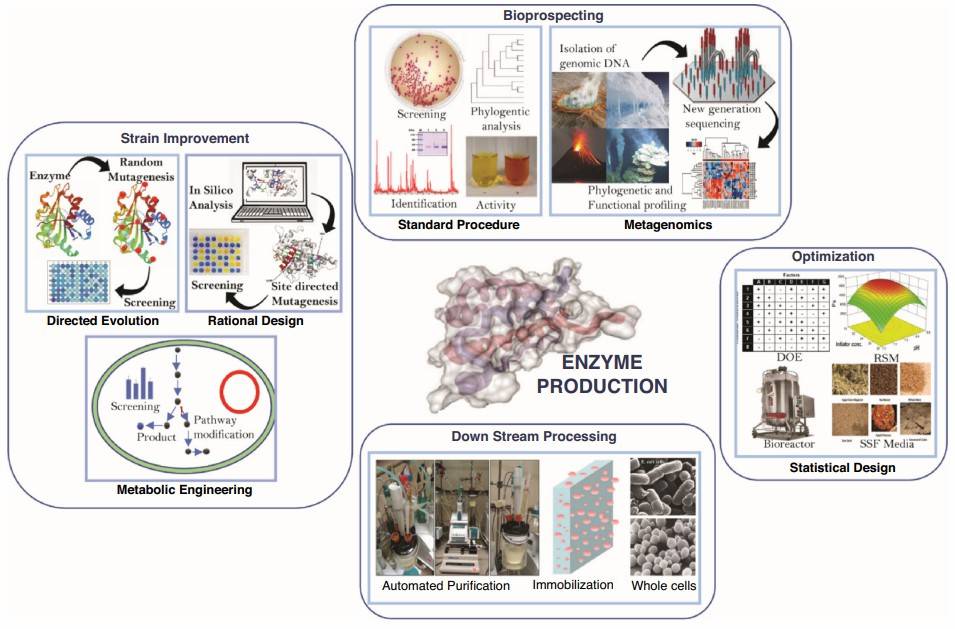

Enzyme Production (Aneesa Fasim, et al., 2020)

Enzyme Production (Aneesa Fasim, et al., 2020)

With our professional team and technology infrastructure, we can respond to customers quickly and offer effective and high quality enzyme production services. We are committed to becoming our customers' preferred enzyme production partner to enable them succeed in the R & D and production cycle.

Core Service Offerings

Our Custom Enzyme Production services are mostly the following:

Expression and purification of enzymes

- Expression of enzymes: this includes identifying appropriate expression systems (prokaryotes, eukaryotes, cell-free expression systems, etc.) and optimizing expression conditions (host cell selection, promoters, optimal culture medium, etc. ).

- Enzyme purification: a range of methods are used, including mechanical (osmotic shock), non-mechanical (ultrasonic disruption), filtration, centrifugation, extraction, precipitation, ultrafiltration, ion exchange chromatography, affinity chromatography, etc.

Enzyme Process Development

- It is mainly concerned with the engineering and optimisation of the enzyme production line such as the selection and optimization of the fermentation tanks, the improvement of oxygen transport and mixture, the use of models and optimization technologies, and the implementation of instruments and control equipment.

- For industrial enzyme manufacturing, especially, the need to consider how to go from the lab to the industry scale — process scale-up and model validation.

Enzyme Scale-Up Production

- These range from the lab scale up to the pilot scale up to the factory scale. What to do about problems that still need to be resolved at this stage is how to maintain enzyme activity, how to manage byproducts in the large production scale, how to optimize reaction conditions to get better yields and lower costs, etc.

- During scale-up, also we have to take into account stability and activity stability of the enzyme, as well as process improvement to increase yield and quality of the enzyme.

Other recommended services

- Immobilized enzyme technology: The stability and reusability of the enzyme can be enhanced by immobilizing it onto a carrier. It is ideal for applications requiring either ongoing reactions or enzyme recovery.

- Enzyme engineering: Gene and protein engineering can change the structure and activity of enzymes to optimise their catalytic efficiency and specificity.

- Offering such services will enable your firm to offer customers complete support in the manufacture and application of enzymes, increasing firm's market presence.

Project Workflow

Our company Custom Enzyme Production service procedure:

Demand analysis and consulting

Scale-up production and quality inspection

Retention services and after sales

- Demand analysis and consulting: First, our customer service team will discuss with you systematically to learn what you are looking for (type of enzyme, production amount, application, etc.). Now we will also offer some preliminary technical guidance and suggestions to help clarify the project objective and viability.

- Schema development: Our R & D team will generate your unique enzyme production scheme as per your requirement. This involves choosing the right host system (e.g. Escherichia coli, yeast, etc. ), optimizing the expression system and figuring out optimal production conditions.

- Preparation and testing: At the laboratory phase, we will process small quantities of enzyme samples and conduct preliminary functional testing and performance assessment. This step can take several rounds to ensure the enzyme's activity and stability meets your needs.

- Scale-up production and quality inspection: After the lab results are positive, we will scale-up production. At this point, we will tightly monitor all aspects of production to ensure consistency and the quality of the products. Meanwhile, we'll execute rigorous quality assurance tests, such as purity test, activity test, and stability test.

- Packaging and shipping: After production, we will seal the product as well to keep it safe and stable during shipment. And the product is safely shipped to you. We also offer detailed guides and technical support to help you use our products in the right way.

- Retention services and after sales: We offer ongoing technical support and after-sales support, such as frequent technical news, solution & optimization recommendations for a custom service. Our aim is to ensure the success of your project and build a healthy relationship in the future.

In this cycle of services, we strive to provide customers with scalable, high-quality, customized enzyme manufacturing solutions.

Case Studies

Efficiency and utilization of heterologous expression enzymes.

Project background:

A farming company wants to discover a new kind of enzyme that would boost the resistance to disease and yields in crops. They cannot satisfy their very demanding requirements for enzyme activity and stability with traditional enzyme expression systems.

Solution:

We constructed a heterologous expression vector and altered the expression conditions to increase the expression of the target enzyme. We are able to make the enzyme more stable and catalytic by combing genetic and metabolic engineering.

Result:

The enzyme dramatically improved crop disease resistance and crop production during field trials, and delivered major value to customers. Our customers are delighted with our technical assistance and custom services, and look forward to continuing our partnership in the creation of new kinds of biocatalysts.

Application Areas

Custom Enzyme Production is useful for many applications and applications across industries and fields.

01

Pharmaceutical industry

Custom enzymes have their importance in the development of new drugs from drug discovery, pharmacology, pharmacokinetics, toxicology, clinical trial design, data management and statistical analysis.

In addition, enzymes are also utilized in API (active pharmaceutical ingredient) production, and enzymes with better catalytic performance and substrate specificity are derived through directed evolution and computational modeling.

02

Food processing

Customized enzymes are primarily employed in food manufacturing for example to enhance food's flavor, texture and nutrition. They can be used to extract natural flavours and pigments and also enhance food preservation and safety.

03

Protection of environment

Enzymes are also used in environmental cleanup, like degrading contaminants and wastewater treatment. They are enzymes that break down organic matter to reduce the quality of the environment.

04

Chemical and light industry

Enzymes are employed in a variety of chemical reactions and manufacturing applications in the chemical and light industry, including biocatalysis, biodegradation, and biosynthesis. These tools maximize the productivity of production and minimise the environmental footprint.

05

Biotechnology research

Enzymes play the main roles in molecular biology, cell analysis, diagnostics and protein analysis. They enable customers to add enzymes for specific product needs, and to finish kit or master mix development.

06

Purification of essential oils

Custom enzymes in the purification of essential oils writ simple obturating essential oils hydrolyze the network of cell wall cells, a more ecological alternative.

Frequently Asked Questions (FAQs)

For customers to understand Custom Enzyme Production services, here are some frequently asked questions and answers:

common Questions and Answers

Q: What is Custom Enzyme Production?

A: Custom Enzyme Production is the customised enzyme production service as per customers need. The enzymes can be used for a large variety of biotechnical applications: molecular biology, gene editing, mRNA production and more.

Q: How do you know what enzymes your company provides?

A: We can generate enzymes of all sizes and shapes, single- or multi-subunit enzymes, labeled and unlabeled enzymes. We can also produce enzymes at the molecular biology scale, bespoke to the customer.

Q: How much enzymes are manufactured by your company?

A: We have 16 liters, 32 litres, and 100 litres of standard fermentation scales we can provide to customers on request.

Q: How does your company manufacture enzymes successfully?

A: We have the means and the skills to take natural nucleases and other enzymes and extract them for purification. We have labs set up specifically to grow cells, extract cells, and purify cells.

Q: What is your company producing for enzymes?

A: We cultivate, harvest, purify and manufacture our enzymes. We use patented microfluidics to discover and develop enzymes faster than ever, and we combine high-throughput screening with a proprietary enzyme library to develop highly selective enzymes.

Q: You have technical support and consulting – does your company?

A: Yes, our scientists will be more than happy to chat with customers about the best configurations for our technology and products to address your application needs.

Q: To what industries could your company's bespoke enzymes be applied?

A: Our designed enzymes are applicable in a broad spectrum of fields including biotechnology, medical, environmental, and agricultural. We are specialized in providing biotechnology-enabled biodegradable solutions to government, NGOs, and industrial clients.

Q: What about "customer special needs" at your firm?

A: Our customer care is particularly strong and we're always able to get any new concept, flavor or recipe issue resolved in a snap. As one of the most advanced specialty enzyme suppliers in the world, we provide the best service to our customers.

Q: What's your company's settlement strategy?

A: We offer a custom settlement process for our customers. We will typically pay at the end of the project duration and contract terms to respect the interests of both parties.

CD Biosynsis specializes in providing custom enzyme production services. Our company is a group of professionals with long experience in this field and believes in offering customers customized enzyme production service by professionals.

We offer not only enzyme production but also the entire operation from initial concept to product. We adopt advanced, quality-control techniques to guarantee every enzyme product batch can meet the customer's requirement. In addition, we also provide individual service plans based on each customer's need. For further queries, please feel free to contact us.

Enzyme Production (Aneesa Fasim, et al., 2020)

Enzyme Production (Aneesa Fasim, et al., 2020)