Enzyme Upstream Process Development is a highly specialized service meticulously designed to optimize the production of enzymes for a wide array of applications. The core aspect of this service involves a systematically structured study that meticulously identifies and effectively resolves potential problems that may arise during production, thus guaranteeing a high-quality enzyme output. We provide a highly customized approach, tailored meticulously to meet the unique needs and requirements of different industries and applications. Our goal is to ensure that enzyme production is optimized, efficient, and meets the highest quality standards.

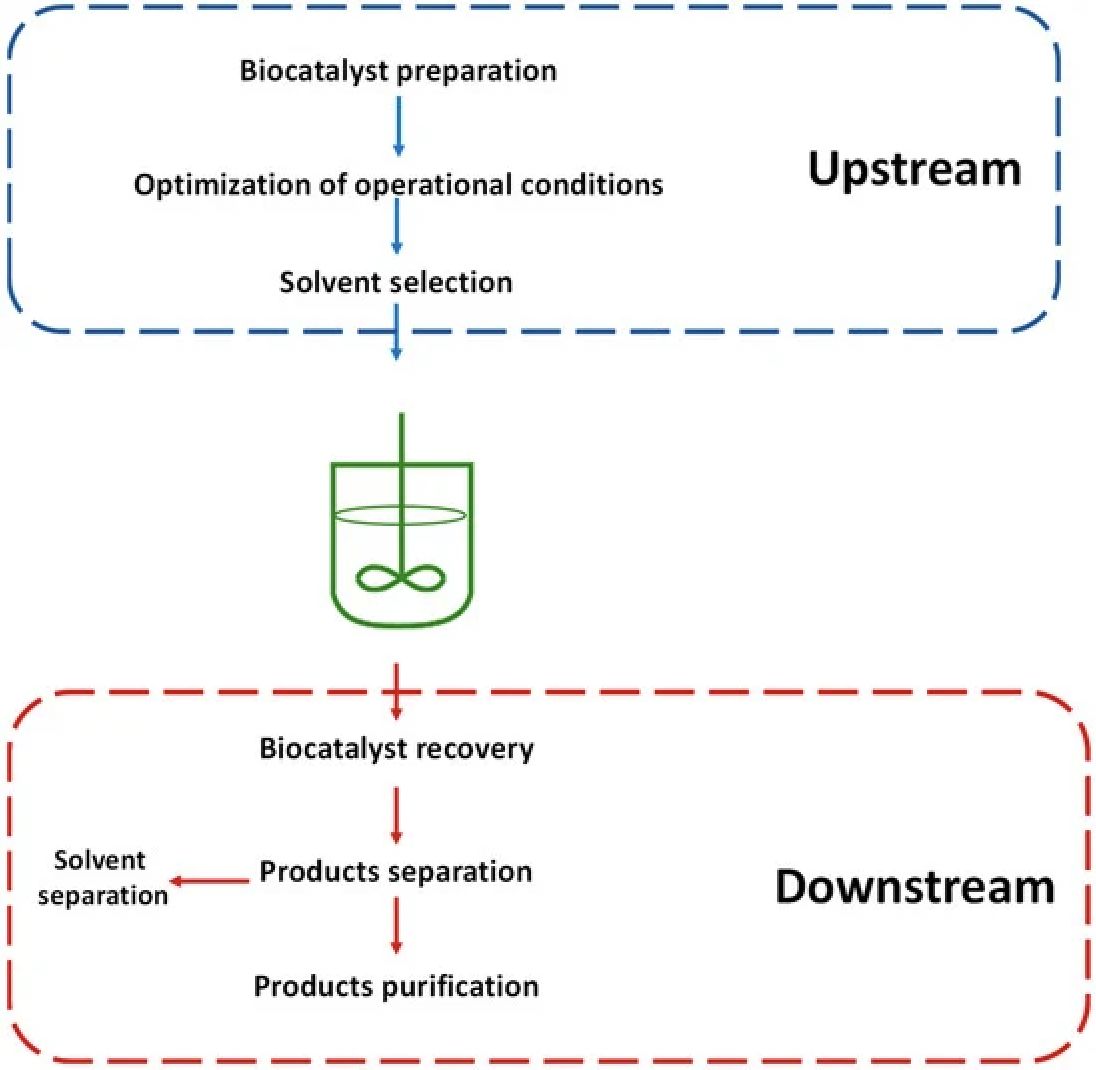

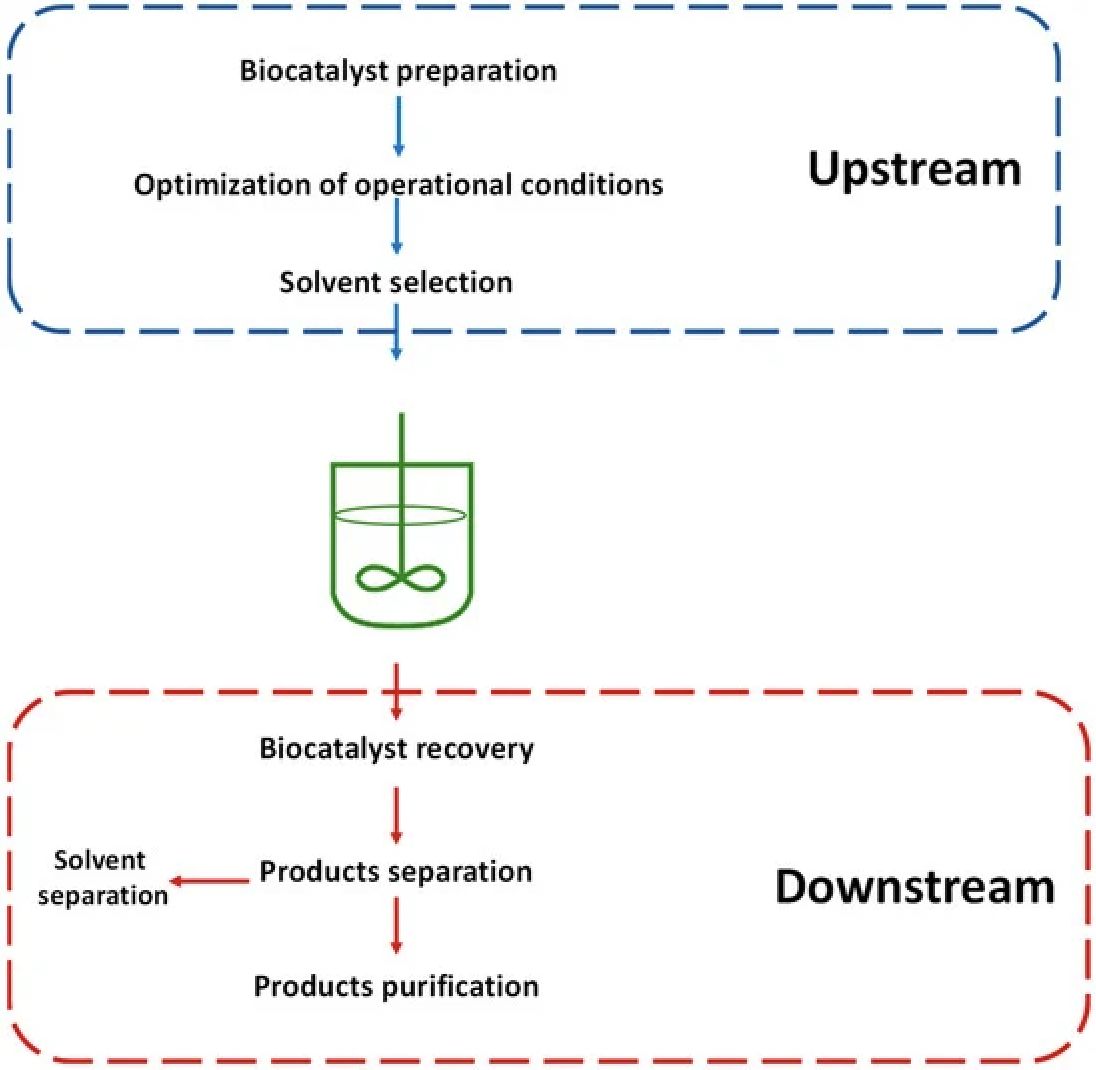

Upstream and downstream processes in enzyme technology (Nadia G. and Rodrigo A. S., 2024)

Upstream and downstream processes in enzyme technology (Nadia G. and Rodrigo A. S., 2024)

Service Process

We are pleased to introduce our carefully developed service process. Designed with great attention to detail, it aims to deliver high-quality service that matches your expectations. This process is fundamental to our operations and works as follows:

- In-depth Consultation: This is the initial stage of our service process. We engage in a detailed consultation with you to understand the specific requirements of your project. This step allows us to gain a comprehensive understanding of your goals and the challenges you might be facing.

- Designing a Customized Plan: Based on the insights gathered during the consultation, we design a customized plan tailored to meet your project's unique needs. This plan covers all aspects of the enzyme production process, from the initial stages of cell culture growth and development to the final step of harvesting the enzymes.

- Executing the Plan: Once the customized plan has been put in place, we proceed to the execution phase. We implement the strategies and steps outlined in the plan, ensuring each stage of the production process is handled with the utmost attention to detail.

- Consistent Monitoring: Throughout the execution phase, we consistently monitor the progress of the project. This allows us to track the production process's effectiveness and make necessary adjustments on the go, thus maintaining the highest level of efficiency.

- Adjustments as Needed: If during the monitoring phase, we identify any areas that may require changes, we promptly make the necessary adjustments. This ensures that the enzyme production process remains optimal at all times.

- Ensuring Optimal Enzyme Production: The final step of our service process is to ensure that the enzyme production is optimal. We employ stringent quality assurance practices to guarantee the highest quality of the final product. This comprehensive and methodical process is aimed at achieving the maximum efficiency and quality in enzyme production.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Biopharmaceutical Production |

Enzyme upstream process development is crucial in biopharmaceutical production for optimizing the production of therapeutic proteins, antibodies, and vaccines. This involves the design and implementation of upstream processes to cultivate host cells, such as mammalian cell lines or microbial systems, and express recombinant enzymes efficiently. The development of robust fermentation or cell culture protocols, media optimization, and bioreactor scale-up strategies are essential for achieving high cell densities and maximizing enzyme yields. Additionally, upstream process development focuses on ensuring product quality, consistency, and regulatory compliance throughout the production cycle, contributing to the reliable and cost-effective manufacturing of biopharmaceuticals. |

| Industrial Biotechnology |

Enzyme Upstream Process Development plays a vital role in industrial biotechnology, facilitating the production of enzymes for various applications. It involves optimizing culture conditions, media composition, and fermentation parameters to maximize enzyme yield and activity. This process development is essential in sectors such as enzyme manufacturing, bio-based chemicals, textile processing, and paper production, enabling the efficient utilization of enzymes for diverse industrial processes, thereby promoting sustainability and cost-effectiveness. |

| Environmental Bioremediation |

Enzyme Upstream Process Development is applied in environmental bioremediation to produce enzymes for the degradation of pollutants. By optimizing upstream processes, such as enzyme production and extraction from microbial sources, researchers can enhance the efficiency and applicability of enzymatic remediation strategies for cleaning up contaminated sites. This application finds use in wastewater treatment, soil remediation, and the cleanup of oil spills, contributing to environmental sustainability and ecosystem restoration efforts. |

| Biofuel Production |

Enzyme upstream process development is essential in biofuel production for optimizing the production of enzymes used in lignocellulosic biomass conversion processes. This includes developing microbial or fungal fermentation protocols to produce cellulases, hemicellulases, and other enzymes involved in biomass degradation. Upstream process development focuses on optimizing substrate utilization, enzyme productivity, and fermentation kinetics to achieve high enzyme yields and activity levels. Additionally, strategies for enzyme recovery, purification, and formulation may be integrated into upstream process development to enhance overall process efficiency and reduce production costs. By optimizing enzyme upstream processes, researchers aim to facilitate the efficient conversion of lignocellulosic biomass into biofuels, such as ethanol or butanol, contributing to the development of sustainable and renewable energy solutions. |

| Agricultural Biotechnology |

Enzyme upstream process development plays a role in agricultural biotechnology for producing enzymes used in crop protection, biostimulants, and plant biotechnology applications. This involves optimizing fermentation or plant cell culture systems to produce enzymes with desired activities and functionalities, such as enzymes for enhancing nutrient uptake, pest resistance, or stress tolerance in plants. Upstream process development focuses on selecting suitable production hosts, optimizing growth conditions, and implementing bioreactor scale-up strategies to achieve high enzyme yields and consistency. Additionally, considerations for enzyme formulation, stability, and application methods may influence upstream process development to ensure the efficacy and commercial viability of enzyme-based agricultural products, contributing to sustainable and resilient crop production systems. |

Case Study

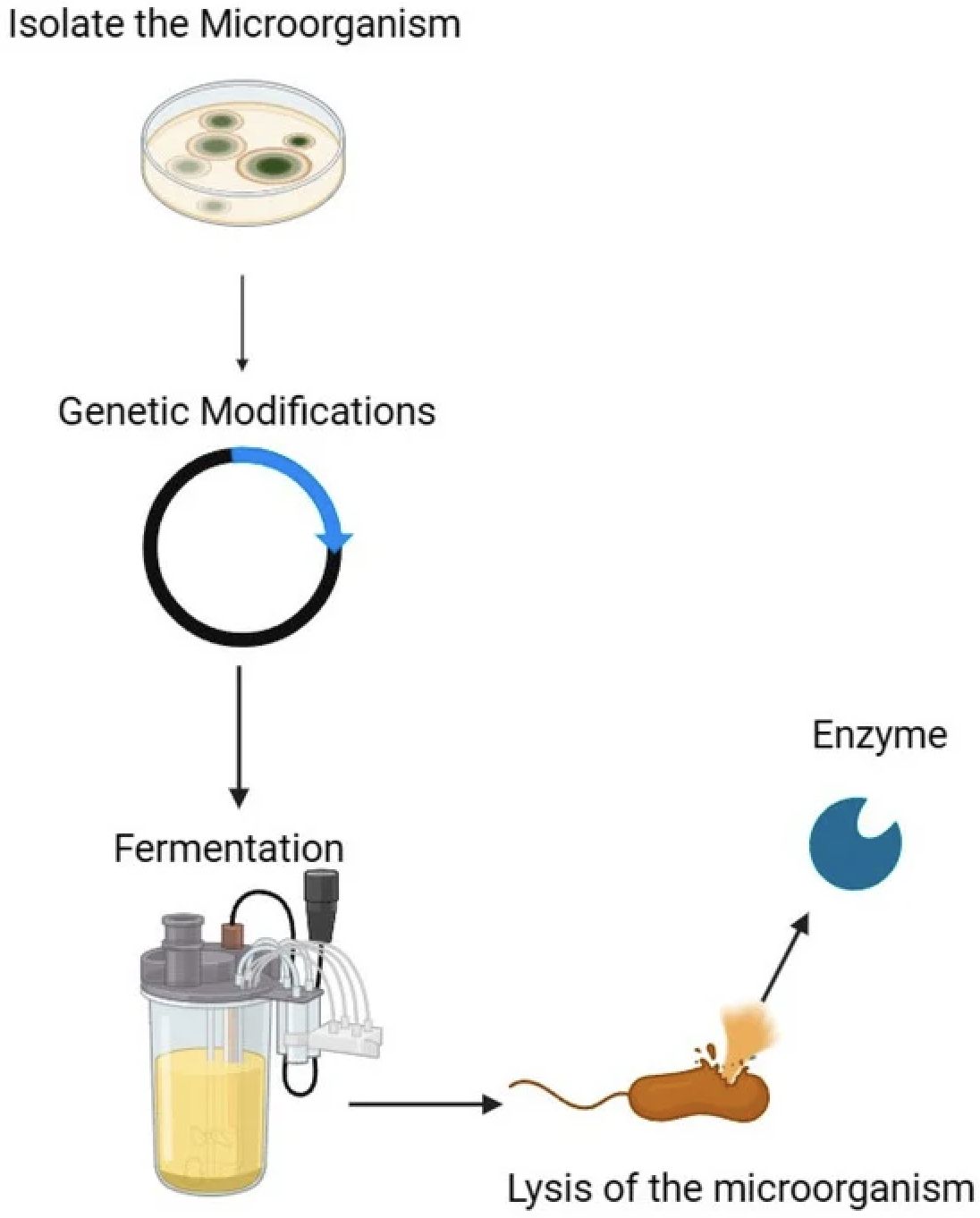

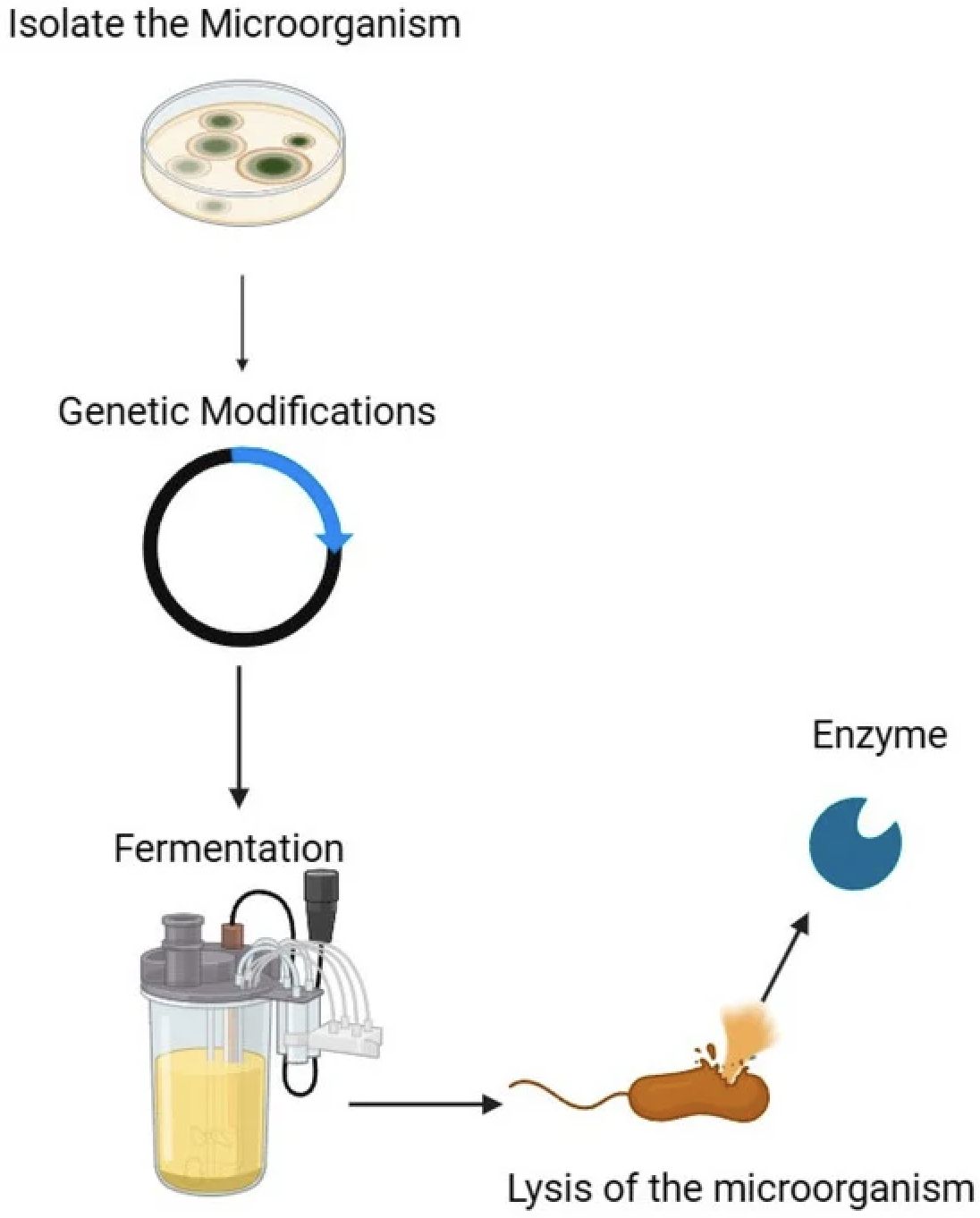

In enzymatic reactions, upstream processes consist of the expression of the enzymes of interest in the cells for their culture, immobilization methodologies for the recovery and stabilization of the biocatalyst, and selection of solvents as part of the reaction medium. Determining a robust biocatalyst to apply as a process catalyst is a challenge due to its intrinsic lability and the need for large-scale enzyme production. For adequate availability of some enzymes, it is essential to follow a series of steps to optimize the production of the enzyme. The figure below shows the enzyme upstream process optimization process, where the microorganisms responsible for enzyme production are isolated from natural sources. Once isolated, understanding their genome becomes crucial as this can be genetically modified to produce more active and stable enzymes.

Enzyme upstream process production (Nadia G. and Rodrigo A. S., 2024)

Enzyme upstream process production (Nadia G. and Rodrigo A. S., 2024)

FAQs

Here's a list of frequently asked questions that provide a deeper understanding of Enzyme Upstream Process Development, its importance, customization aspects, time duration, cost-effectiveness, safety measures, potential beneficiaries, and the way to avail of this service, along with information on the success rate. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: Can you elaborate on what Enzyme Upstream Process Development is?

A: Certainly, Enzyme Upstream Process Development is essentially a scientifically rigorous process that focuses on optimizing the production of enzymes. This process encompasses a vast range of activities, starting from the initial stages of cell culture growth and development, right through to the final step of harvesting the enzymes. Each stage is meticulously planned and executed to ensure optimal enzyme production.

Q: Why would you say this process is critical?

A: The significance of this process truly cannot be overstated. It plays a pivotal role in determining the final product's quality and quantity. By optimizing enzyme production, we can ensure that the enzymes produced are not only of the highest quality but also produced in quantities substantial enough to meet the ever-growing industrial demands.

Q: Could you explain more about the 'Customization' aspect?

A: Of course, the customization aspect of this service is a unique feature that allows us to modify the process to align with the specific needs of different applications and industries. Through this customization, we can ensure that the end product is perfectly suited for its intended application, thereby enhancing its effectiveness and efficiency.

Q: How much time should one expect the whole process to take?

A: The duration of the process can vary quite a bit, largely depending on the specific details of the project. Factors such as the type of enzyme being produced, its intended application, and the desired quantity can all significantly influence the timeline. However, rest assured that we strive to complete the process in the most efficient manner possible.

Q: Would you say this process is cost-effective?

A: Absolutely, one of our primary aims is to provide our clients with a solution that is not only effective but also cost-effective. We work diligently to maximize enzyme production without ever compromising on the quality, thereby ensuring you get the best value for your investment.

Q: How is safety ensured during the process?

A: Safety is one of our top priorities. Our team of highly trained experts strictly adheres to all safety protocols during the process. We take every precaution to ensure safety at all stages of the process.

Q: Can you name some applications that can benefit from this service?

A: This service has a wide range of potential beneficiaries. Industries such as pharmaceuticals, biotechnology, food and beverages, and many others can greatly enhance their production efficiency and product quality through our service.

Q: How can I avail myself of this service?

A: To avail of this service, you can simply reach out to us directly to discuss your project. We'll work closely with you to understand your needs and provide a customized solution that perfectly fits your requirements.

Q: Can you share some information on the success rate of the process?

A: We take great pride in our high success rate in optimizing enzyme production. Our effective process significantly contributes to improving the efficiency and quality of the end product, leading to enhanced customer satisfaction.

Upstream and downstream processes in enzyme technology (Nadia G. and Rodrigo A. S., 2024)

Upstream and downstream processes in enzyme technology (Nadia G. and Rodrigo A. S., 2024) Enzyme upstream process production (Nadia G. and Rodrigo A. S., 2024)

Enzyme upstream process production (Nadia G. and Rodrigo A. S., 2024)