Research background:

The use of renewable substrates such as glycerol to produce 3-HP is a promising method. However, the production of 3-HP from glycerol requires vitamin B-12, which hinders its economic feasibility. Research has shown that using glycerol as a substrate β- The alanine pathway can efficiently produce 3-HP. Therefore, a comparison was made between substrate glycerol and glucose, and the results showed that when glycerol was used as the substrate, the production of 3-HP was more than twice that of glucose. Then, by overexpressing NADP+dependent glyceraldehyde-3-phosphate dehydrogenase and inhibiting the endogenous gapA gene, the reducing ability of cells was regulated, resulting in a 91% increase in 3-HP titer. Finally, the toxicity of 3-HP accumulation is reduced by overexpressing a hypothetical output (YohJK). The final strain was fed and fermented in batches to produce 72.2 g/L 3-HP, with a productivity of 1.64 g/L/h.

Research content:

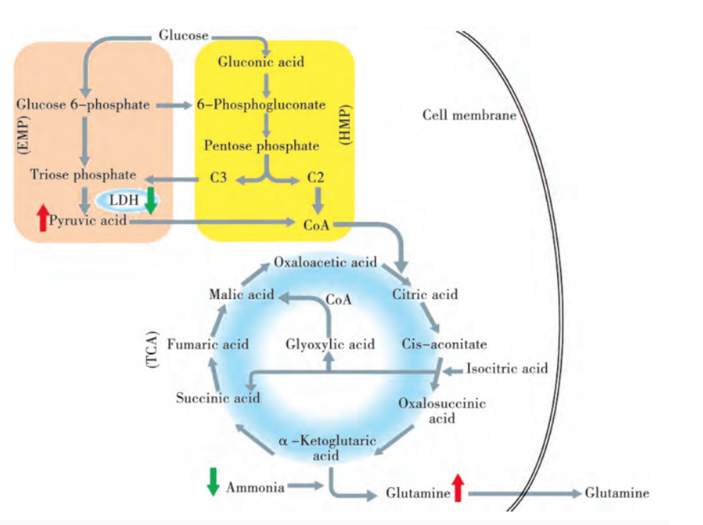

Due to the production of 3-HP β- The alanine pathway is not limited to specific carbon sources, and glycerol is a cheap and abundant byproduct in biodiesel production. Therefore, the author speculates that glycerol may be a better substrate as it oxidizes less than glucose. To verify this hypothesis, flux variability analysis (FVA) was conducted using glucose or glycerol as carbon sources, and the results showed that glycerol was superior to glucose in producing 3-HP. The amount of 3-HP produced using glycerol as the sole carbon source is more than twice that of glucose, and 30% more than a mixture of glucose and xylose, reaching 1.68 ± 0.01 g/L, confirming that this substrate with a higher degree of reduction is more suitable for the production of 3-HP. In addition, other process variables were studied, including temperature, induction time, inducer type (IPTG and lactose), and inducer concentration. It was found that the optimal temperature for 3-HP generation was 34 ℃.

In order to further increase the production of 3-HP, the required reducing force during the production process was considered. Therefore, improvements were made to the oxidation-reduction of NAPD+dependent GAPDH reactions, verifying the effects of the gapB gene of Bacillus subtilis and the gapN gene expression (non phosphorylation) of Bacillus thuringiensis and Streptococcus suis on the target product. It was found that overexpression of gapN from Streptococcus suis resulted in the highest 3-HP production of the strain, which was 3.21 ± 0.23 g/L, and was the highest 3-HP production obtained in the shake flask experiment.

Product tolerance is another bottleneck in bioprocess development, and to address this issue, overexpression of the assumed 3-HP efflux expressed by the operon yohJK is necessary. Then, glycerol was used as the substrate for supplementary batch fermentation at a temperature of 34 ℃. After 44 hours, it reached 72.2 g/L with a productivity of 1.64 g/L/h.

Related recommendations

Strain Engineering for 3-Hydroxypropionic Acid

Metabolic Engineering and Pathway Design

Chemical production Metabolic pathways Engineering

Strain Development Service

Bacterial Strain Modification