With the increasing awareness of environmental issues and sustainability, the demand for products such as environmental protection, high-quality food, and cosmetics is also increasing. At this critical moment, microorganisms become potential key players, providing important solutions for these seemingly completely different problems.

Microbial Cell Factory: A Wonderful Revolution

The field of systemic metabolic engineering was founded by Academician Sang Yup Lee of the renowned Korean Institute of Advanced Science and Technology, with the aim of fundamentally changing the next generation of biological industry by effectively developing microbial factories, thereby replacing the existing heavily petroleum dependent chemical industry.

Academician Sang Yup Lee (source: Quanwang)

Using a systematic metabolic engineering strategy, researchers have created a series of high-performance microbial cell factories capable of producing a variety of food and cosmetic compounds. These substances include natural substances such as heme and nine compounds of zinc cyanogens; Enhance the aroma and color of synthetic meat; Functional natural pigments, such as lycopene and long leaf carotene, are widely used in food and cosmetics, as well as methyl benzoate, a grape derived compound, widely used to convey grape aroma in food and beverage manufacturing.

In addition, bio based monomers are also an important research area for the team of Academician Sang Yup Lee, such as the metabolic modification of high yield nylon 5 precursor pentolactamide by Corynebacterium glutamicum.

Potential colors that may be produced by cell factories (source: KAIST Metabolic and Biomolecular Engineering National Research Laboratory)

Recently, the team published an invited review titled “Microbial Metabolic Engineering Systems for Food and Cosmetics Production” in Nature Review: Bioengineering. The article points out that the production of amino acids, proteins, fats and fatty acids, vitamins, spices, pigments, alcohols, functional compounds, and various other food and cosmetic additives by microbial cell factories is a noteworthy case.

The article introduces the system metabolic engineering strategy, which can drive the development of industrial microbial cell factories to produce a wider range of food and cosmetic compounds in an economically feasible and eco-friendly manner.

For example, the team demonstrated how the microbial fermentation process utilizes non edible biomass as animal feed or fertilizer to produce protein and amino acids with high nutritional value, thereby promoting an increase in world food production and stable supply. In addition, by promoting feasible alternative meat production, dependence on animal protein can be reduced, thereby reducing greenhouse gas emissions and environmental pollution related to livestock and fish farming.

Produce food and cosmetics in an easier, environmentally friendly, and sustainable way

Academician Sang Yup Lee believes that the task of engineers is to use science and technology to improve the world.

“The continuous development and active utilization of system metabolic engineering will greatly help alleviate and solve the problems caused by the food crisis and climate change,” he said.

Microorganisms can provide an eco-friendly and cost-effective alternative to their production, and address supply and ethical, resource issues.

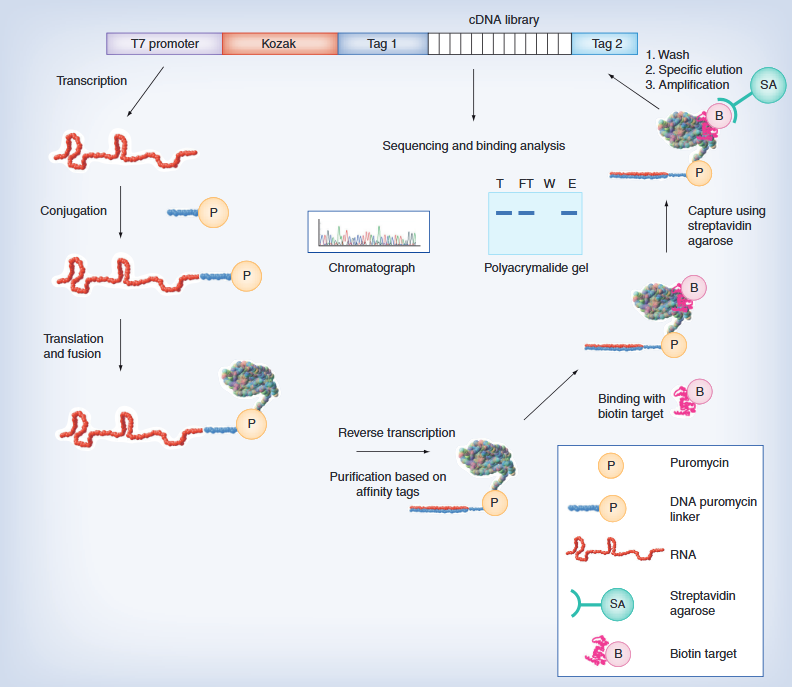

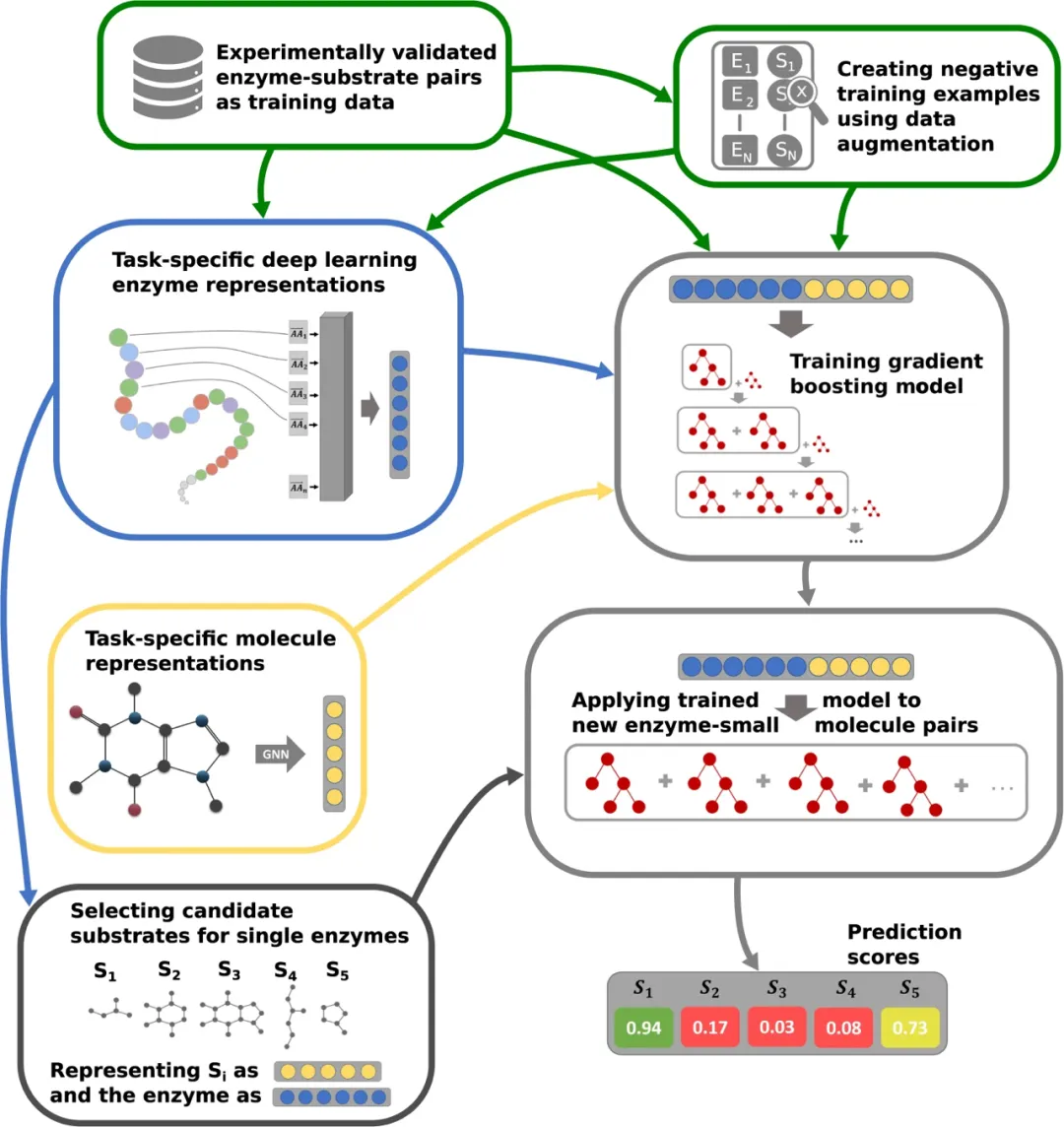

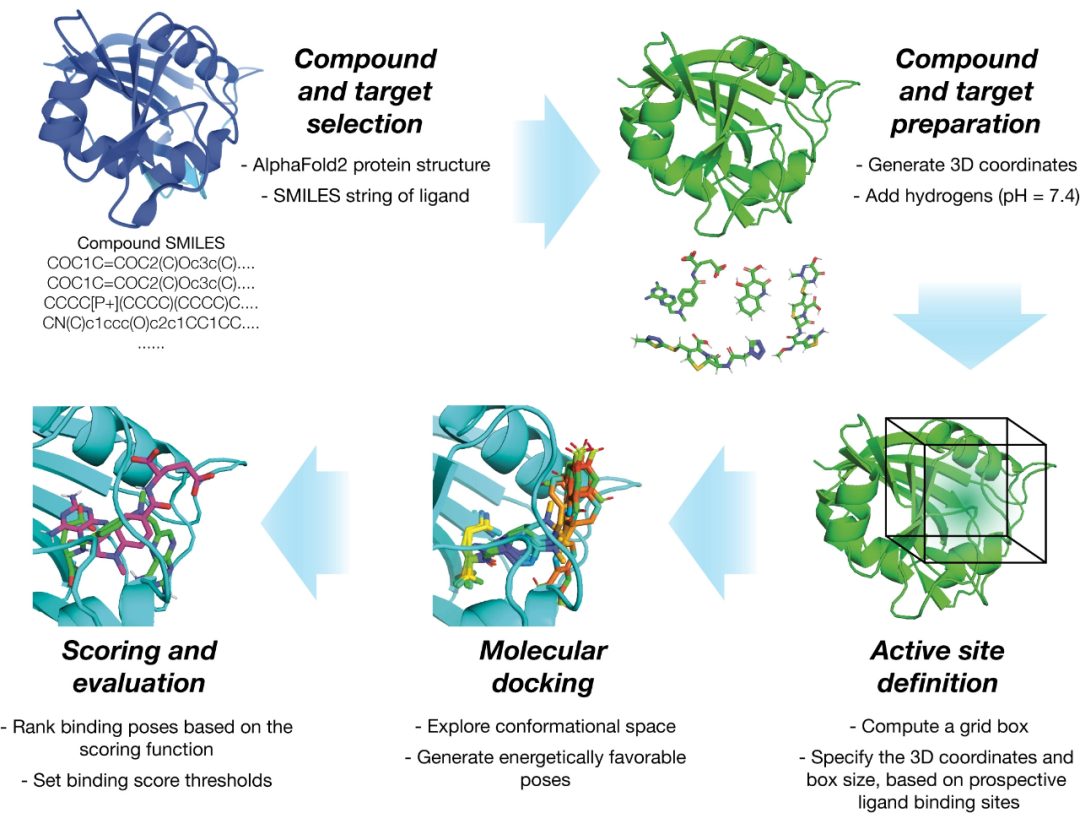

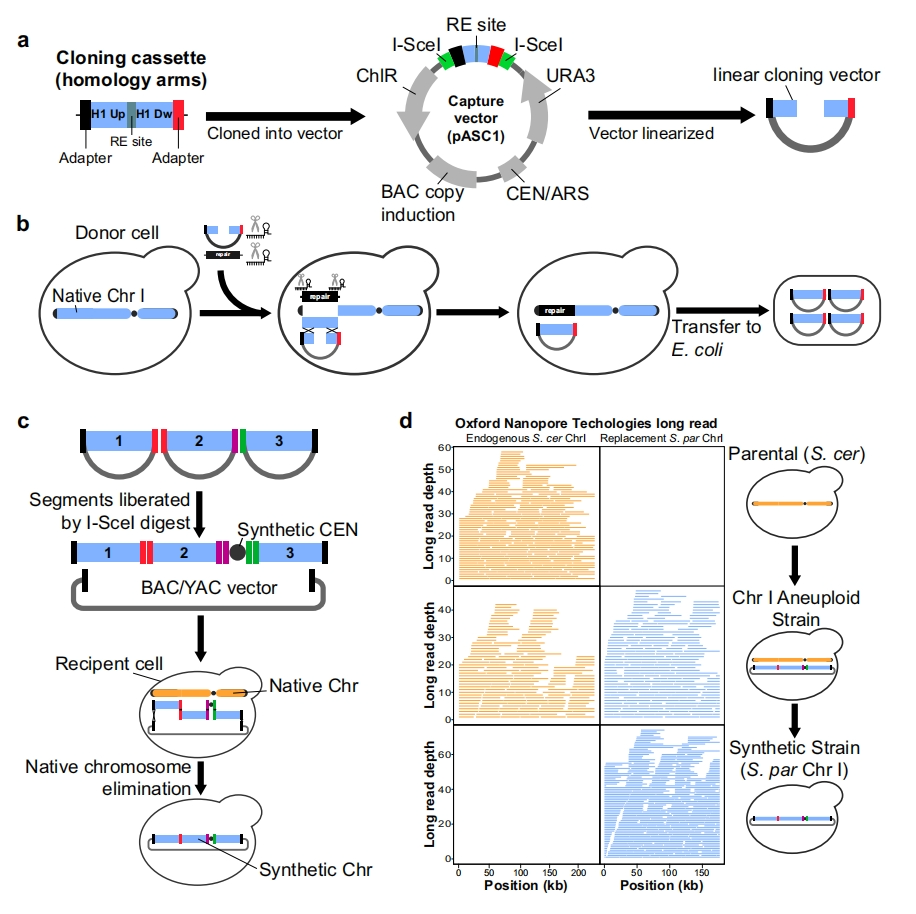

Systematic metabolic engineering strategies for improving metabolic processes within microbial cell factories. (Source: KAIST Metabolic and Biomolecular Engineering National Research Laboratory)

For example, the article points out that natural compounds such as vanillin or methyl aniline have a vanilla or grape flavor in various foods and currently come from plants, resulting in limited yields and high costs.

Other additives, including the widely used coloring agent calcium protein in cosmetics and food, are extracted from sea urchins that only live in specific cacti. Currently, omega-3 fatty acids from sharks or fish liver pose ethical and resource concerns.

Another author of the work, Professor Cui Qingrong, also emphasized the progress made in the production of foods such as cocoa butter (a basic component of cocoa fermented chocolate) and monosodium glutamate (a seasoning produced through microbial fermentation). He added, “In the future, we will be able to obtain a wider variety of food and cosmetics through microbial cell factories, and produce them in a more accessible, environmentally friendly, and sustainable way.”

Related recommendations

DHA Omega-3 Fatty Acid Strain Engineering

DNA Synthesis and Assembly

Genetic Engineering and Gene Editing

Genetic Circuit Engineering

Metabolic Engineering and Pathway Design

Strain Development Service