Introduction

Compared with methods such as chemical synthesis, using engineering microorganisms to produce high value-added products is a very attractive approach. However, when long and complex compound synthesis pathways are introduced into cells, such as isoprene like compounds, cells activate some regulatory mechanisms to respond to changes in the external environment and achieve their optimal growth; The existence of these mechanisms has also become a major obstacle in redirecting metabolic flux away from natural growth optimization pathways and towards target engineered metabolic pathways.

The substrate inhibition mechanism at the enzyme level is one of the main metabolic regulation mechanisms of microorganisms; When the substrate concentration in the environment exceeds a certain threshold, cells will trigger a substrate inhibition mechanism to prevent the catalytic conversion of the substrate, limit the flux of the target synthesis pathway, cause intermediate volume accumulation, pathway disruption, and product spectrum changes, ultimately hindering the synthesis of the target end product. At present, various methods have been explored to address this limitation, such as enzyme immobilization, two-phase distribution bioreactor systems, batch substrate feeding strategies, and protein engineering. However, these methods only work when the initial substrate constitutes substrate inhibition, and their application is very limited. Therefore, it is crucial to develop new methods to bypass enzyme inhibition and construct robust strains with high productivity.

This article constructs a carotenoid producing strain using lipolytic yeast as the chassis cell; Due to the strong substrate inhibitory effect of lycopene on lycopene cyclase during the synthesis of carotenoids, downstream products β- The production efficiency of carotene is very low. To address this issue, this article has developed two independent strategies that almost completely bypass lycopene substrate inhibition and achieve efficient production of carotenoids. 1) By using phylogenetic information and structural guidance in protein design, mutants that eliminate substrate inhibition without altering enzyme activity were obtained, significantly improving β- Carrot production. 2) Establish a GGPPS mediated metabolic flow limiter to regulate the rate of lycopene formation and maintain intracellular lycopene levels below the “inhibition threshold”, thereby preventing substrate inhibition and increasing its efficiency β- The yield of carotene. By cleverly using the above methods and carefully allocating cell resources, the resulting strain can produce 39.5 g/L in a fermentation tank β Carotene (98% selectivity), with a productivity of 0.165 g/L/h. In addition, by cleverly utilizing the substrate inhibition effect, we can also shift the main product towards lycopene, achieving a lycopene titer of 17.6 g/L and a yield of 0.073 g/L/h. Overall, the research findings of this article emphasize the importance of eliminating substrate inhibition in engineering cell factories and provide a method for the biotechnology production of high-value compounds.

Results:

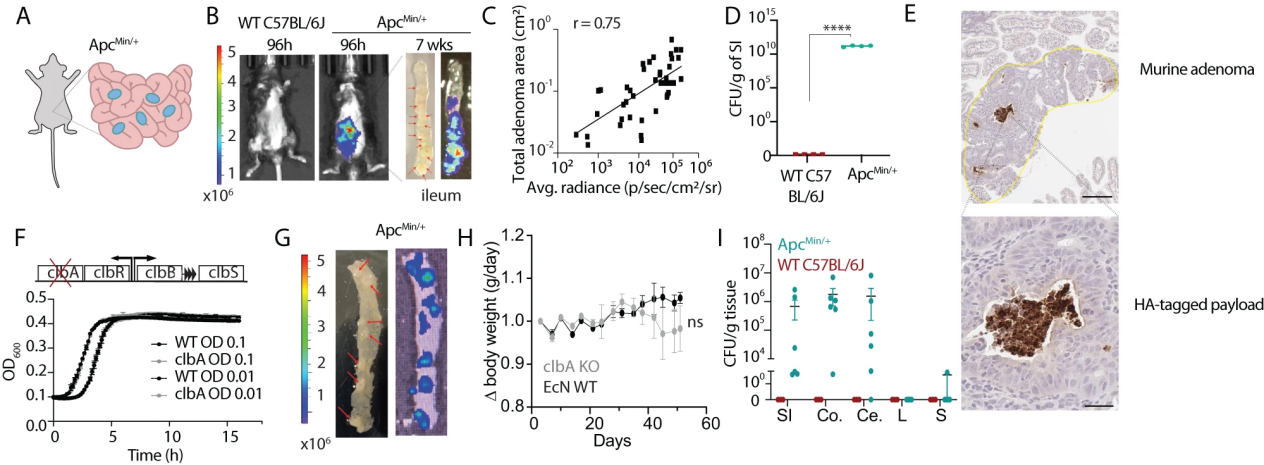

1. Substrate inhibition of lycopene cyclase limits the synthesis of carotenoids

Y. Polylitica β- The synthesis of carotene requires the heterologous expression of three genes: octahydrolycopene synthase, octahydrolycopene dehydrogenase, and lycopene cyclase. In addition, GGPPS is a key enzyme in the metabolic flow to the carotenoid synthesis pathway (Fig.1a). Due to Y Lipolytica contains endogenous GGPPS, therefore, this article integrates the gene expression boxes of different sources of octahydrolycopene dehydrogenase and octahydrolycopene synthetase lycopene cyclase bifunctional enzymes (X. dentrohus derived CrtE+CrtYB and M. circuitlloides derived CarB+CarRP) into Y At the TRP1 position of the lipolytica po1f strain, strains YLMA01 and YLMA02 were obtained. After fermentation testing, it was found that YLMA02 β- The yield of carotene is 4.12 times that of YLMA01, so YLMA02 was chosen for subsequent research (Fig.1b). Due to YLMA02 β- The titer of carotene is very low, so another copy of XdGGPPS (GGPPS from X. dendrohou) is introduced to β- Increase the titer of carotene to 0.48 g/L; At the same time, the accumulation of lycopene also increases (Fig.1c), indicating that the low cyclization efficiency of lycopene is a bottleneck problem. To address this issue, multiple methods have been developed, such as increasing the copy number of the lycopene cyclase gene, deleting or mutating the P domain of the bifunctional enzyme CarRP to make it a specific cyclase, and introducing other lycopene cyclases (EuCrtY, PaCrtY, PfCrtY, HpCrtY). However, this issue has largely not been resolved, indicating that the protein level of lycopene cyclase may not be the main limiting factor.

Due to the fact that lycopene is the only accumulated precursor and the addition of additional copies of various lycopene cyclases cannot avoid this problem, the author speculates that excessive lycopene inhibits the activity of lycopene cyclases through substrate inhibition mechanisms (Fig. 1a). To verify this hypothesis, the author conducted in vitro enzyme analysis to investigate the possible correlation between lycopene cyclase activity and lycopene concentration. The results showed that there was a biphasic relationship between the activity of lycopene cyclase and lycopene concentration: the enzyme activity initially increased with the increase of lycopene concentration, but decreased when the lycopene reached a higher concentration (Fig.1d).

Fig.1 lycope cycle shows the substrate inhibition effect

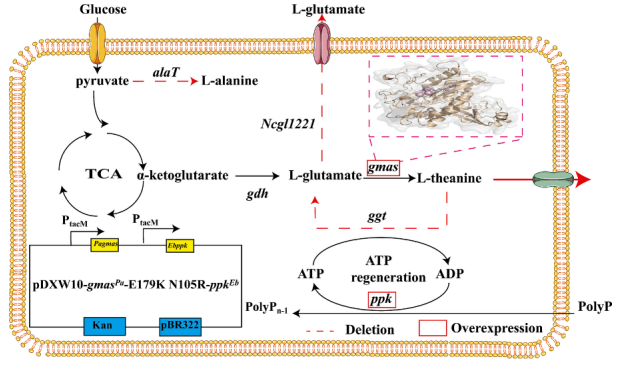

2. Structurally guided protein engineering completely eliminates substrate inhibition

A computational model for the R domain (lycopene cyclase) of CarRP was established using the transform restricted Rosetta (TrRosetta) platform. In addition, evolutionary information is used to generate a location specific scoring matrix (PSSM) from multiple sequence alignments to predict enzyme regions that can eliminate substrate inhibition after mutations. Create single and double amino acid substitutions based on PSSM information and cluster to ensure maximum accumulation of tested mutants. Use PAM30 to calculate the distance between sequences and subdivide them, maximizing the information obtained through initial screening. Through this method, a set of candidate genes (50) were obtained, with mutations distributed throughout the entire enzyme (Fig.2a). In addition, this article tested the performance of each mutant β- Selective changes in carotenoids. As shown in Fig As shown in 2b-c, the Y27R, V175W, and T31R-F92W mutants significantly increased gene expression without affecting it β- The selectivity of carotene and the improvement of yield indicate a reduction in substrate inhibition. Among them, Y27R completely eliminated substrate inhibition without reducing enzyme activity (Fig.1d), ultimately producing 2.38 g/L β- Carotenoids (Fig. 2c) have a selectivity of 98% (wild type 18%, Fig. 2d).

Subsequently, this study investigated the presence of mutant Y27R at a relatively high rate of precursor/substrate formation β- Can the carotene pathway maintain its characteristic of minimal substrate inhibition. Therefore, in expressing Y27R β- Four key enzymes involved in the methylvalproic acid (MVA) pathway are overexpressed in the carotene producing strain YLMA 11: tHMGR, ERG12, IDI, and ERG20. The results showed that while maintaining a high selectivity of 97.8%, β- The titer of carotene was increased to 3.43 g/L (Fig. 2e). In addition, after introducing the synthetic isoprenol utilization pathway (IUP) – overexpression of choline kinase (CK) and isopentenyl phosphate kinase (IPK), β- The yield of carotene increased by 23% (4.22 g/L) without any loss of selectivity (YLMA15, Fig. 2e). These results indicate that the recombinant non-substrate inhibition pathway is effective in high isoprene flux strains and is not affected by intracellular precursor/substrate levels.

Fig. 2 Abolishment of substrate inhibition through process engineering

3. GGPPS metabolic flow limiter manages substrate inhibition of lycopene cyclase

The author hypothesizes that reducing the formation rate of lycopene (relative to its conversion rate) may potentially maintain the intracellular concentration of lycopene at a sub inhibitory level, but this process requires fine-tuning to prevent the formation rate of lycopene from weakening too much, ultimately leading to an overall decrease in the production rate of the final product. Therefore, this article creates a metabolic flow limiter at the branch point of the FPP node to regulate the flux to lycopene and ensure that the amount of lycopene is maintained at a sub inhibitory level (Fig. 3a). For this purpose, the author screened five GGPPS with different catalytic efficiencies. Compared to GGPPxd, the other four GGPPSs showed lower yields (Fig. 3b), indicating that they have lower lycopene synthesis flux. Introducing these low activity GGPPSs into strain YLMA02 resulted in a decrease in lycopene levels, β- An increase in carotene production. When using GGPPsa from Sulfolobus acidocalarius, β- The yield of carotene reached 1.26 g/L, with a selectivity of 92.5% (Fig. 3c). Lycopene and β- The temporal variation of carotene concentration further confirms this point (Fig. 3d). Interestingly, although the expression of GGPPsa (YLMA25) slightly reduces the flux of carotenoid synthesis, it bypasses substrate inhibition and directs all carbon fluxes β- The formation of carotene achieves a comprehensive balance of pathways; This phenotype is similar to that of the Y27R mutant (YLMA11, Fig. 3d). In contrast, the strain YLMA03 expressing GGPPxd leads to the rapid accumulation of lycopene, triggering substrate inhibition and preventing its transformation into β- Carotenoids (Fig. 3d). These results indicate that GGPPS mediated metabolic restrictors can effectively alleviate substrate inhibition, regulate the flux of lycopene upstream and downstream, and optimize its conversion to β- Carotenoids. To narrow the gap between our two engineering strategies for reducing substrate inhibition β- We have introduced additional copies of GGPPS mediated flux flow limiters (Fig. 3e) to address the gap in carotene production (Fig. 2c and Fig. 3c), which not only β- The biosynthesis of carotene was increased to 2.13 g/L, and its selectivity was further maximized (from 92.1% to 98.1%, Fig. 3e). Furthermore, similar to previous results, overexpression of MVA and IUP resulted in β- The yield of carotene reached 3.72 g/L without affecting selectivity (Fig. 3f). This further emphasizes the fact that once the substrate inhibition problem is resolved, the pathway can operate efficiently.

β- The product spectrum of carotene and lycopene can be altered by altering the activity of GGPPS in the body (Fig. 3b-c). Therefore, highly active GGPPxd can be used to reconstruct a specialized lycopene producing strain. At the same time, after introducing the CarRP E78K mutant, the strain produced 2.62 g/L of lycopene and undetectable β- Carotenoids (Fig. 3g). By overexpressing the MVA pathway and introducing IUP, the yield of lycopene further increased, reaching a titer of 3.09 g/L.

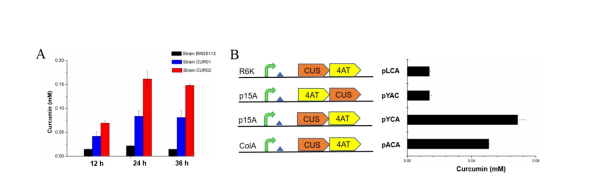

4. Allocating isoprene and lipid synthesis to increase intracellular carotenoid accumulation

Liposomes can form hydrophobic bags, promoting the isolation and storage of lipophilic isoprene products. However, increasing the supply of triacylglycerol (TAG) may enhance the storage of isoprene like compounds, but this comes at the cost of acetyl CoA, which is a common precursor for isoprene like and lipid synthesis (Fig. 4a). Therefore, carbon flux needs to be optimally distributed between lipid and isoprene like synthesis to ensure sufficient lipid supply to encapsulate the generated isoprene like compounds, while not absorbing too much acetyl CoA from the MVA pathway. Due to the fact that lipid synthesis ability can be controlled by the C/N ratio of the culture medium, the author cultured in different carbon nitrogen ratios (C/N) of the culture medium β- The strain YLMA15 of carotene. The results showed that as the carbon to nitrogen ratio increased, the lipid content of cells also increased (Fig.4b), while the total biomass decreased. When cultured in Y10P10D50 (10 g/L yeast extract, 10 g/L peptone, and 50 g/L glucose) with a C/N ratio of 9:1, β- The production efficiency of carotene is the best, with titers of 7.5 g/L and 360.8 mg/g DCW (Fig. 4c). Deviation from this optimal condition can lead to β- The level of carotene decreased. This is consistent with the author’s expectations and highlights the importance of optimal balance between carotenoid and lipid biosynthesis. The optimal Y10P10D50 culture medium was applied to the lycopene producing strain (YLMA34), and after 5 days of fermentation, the lycopene concentration was 8.02 g/L.

Fig. 4 Balancing acetate CoA distribution between lipid and isoprenoid synthesis benefits carotinoid accumulation

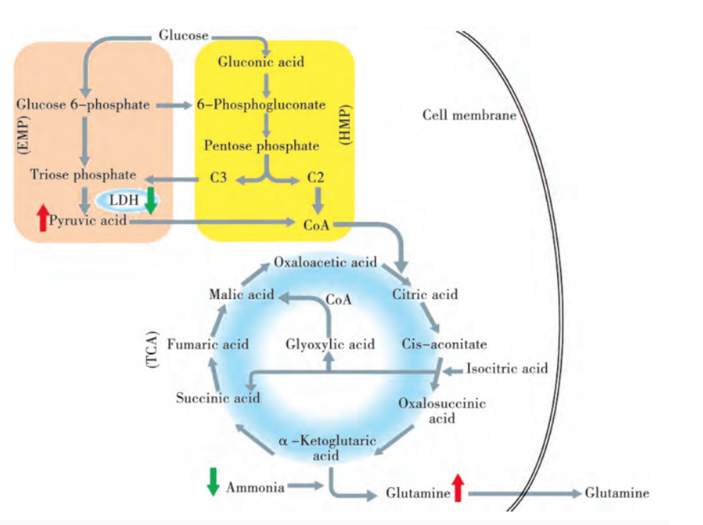

During the stable period of sugar depletion, intracellular lipid degradation products are used to supply carotenoid synthesis

In the fermentation experiment of strain YLMA15, we found that during the stable period, even if the glucose in the culture medium is depleted, β- The content of carotene continues to rise (Fig. 5a). The author believes that it may be Y Lipolytica utilizes previously stored triacylglycerol as an alternative carbon source to supply the formation of carotenoids. To verify this hypothesis, the author characterized the cells and their intracellular lipids before and after glucose consumption. During the entire fermentation process, the lipid content begins to increase and reaches its maximum on the 3rd day. Afterwards, when glucose is completely consumed, the lipid content rapidly decreases (Fig. 5a). However, despite a decrease in lipid content, β- The carotene content continues to rise, far exceeding the glucose consumption point (Fig. 5a), indicating that TAGs are used to maintain metabolic activity and carotenoid synthesis. The microscopic visualization of the fermentation process is consistent with this hypothesis. When glucose is present in the system within the first 3 days, lipid droplets within the cells gradually aggregate into liposomes, isolating the resulting β- Carotenoids; In the later stage of fermentation, due to the decomposition of TAG, the liposomes are no longer visible, leading to the accumulation of β- Carotenoids are more dispersed in cells.

5. Due to the degradation of TAG mainly through β- Oxidation generates acetyl CoA (Fig. 4a), which is likely a stable period of glucose depletion β- The synthesis of carotene provides a carbon backbone. To verify this hypothesis, YLMA15 was cultured in YNB medium containing uniformly labeled [U-13C6] glucose and naturally abundant stearic acid. After joining through β- After oxidizing and decomposing the metabolized stearic acid, a large number of unlabeled IPP/DMAPP and GGPP were observed within 24 hours of cultivation, which were synthesized β- The main precursor of carotene (Fig. 5b-c). These results indicate that by β- Acetyl CoA formed by oxidation can indeed support the MVA pathway and ultimately promote β- The formation of carotenoids. Therefore, this may be the mechanism by which cells convert TAG into carotenoids during the stable stage of glucose consumption.

Fig. 5 Cellular lipstick drive carotinoid biosynthesis through β- Oxidation during stationary phase after glucose completion

6. Bioreactor culture and fermentation

After bioreactor optimization, the total yield of strain YLMA15 β- The titer and content of carotene were 39.5 g/L and 494 mg/g DCW, respectively, with a yield of 0.165 g/L/h (Fig. 6a-c). Similarly, the bioreactor fermentation yield of lycopene producing strain YLMA34 was 17.6 g/L (313 mg/g DCW), and the yield was 0.073 g/L/h (Fig. 6d-f). It is worth noting that during the amplification process, strain YLMA15 affected β- The selectivity of carotene remained unchanged (98% in the batch feeding bioreactor and 97.9% in the shaking flask). These data demonstrate the robustness of our engineering strategy in high-volume and high cell density fermentation. (Translated by Gao Songfeng)

Fig. 6 Bioactor referral of β- Carotene and lycopene engineered Strains

Recommended Services and Products

|

Synthetic Biology PlatformExplore BioSynsis’ Synthetic Biology Platform to accelerate your research and innovation in the field of synthetic biology. |

|

Protein EngineeringDiscover BioSynsis’ Protein Engineering services to advance your protein-related projects and research. |

|

Protein Structure DeterminationEnhance your research with BioSynsis’ Protein Structure Determination services for detailed insights into protein structures. |

|

Genome Enzyme MiningDiscover novel enzymes with potential industrial applications or enzymes involved in specific biochemical pathways. |