Research background:

Phenylpropanoid compounds such as p-CA are important precursors for the synthesis of various plant secondary metabolites, including stilbenes, flavonoids, and lignans. These compounds have pharmacological significance due to their beneficial health properties. Although it is feasible to extract or chemically synthesize p-coumaric acid from plant raw materials, the use of glucose for microbial synthesis of p-coumaric acid has the advantages of low cost and high resource utilization. This study utilized Corynebacterium glutamicum as a raw material to produce plant polyphenol precursor p-coumaric acid from glucose.

Research content:

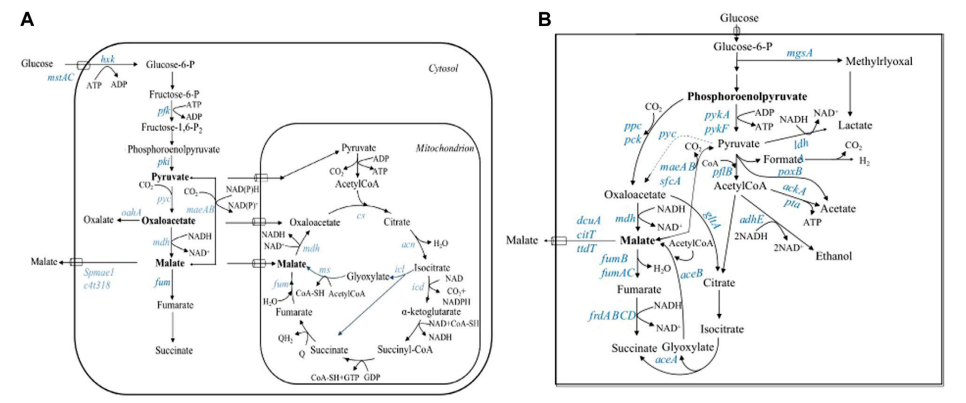

1. Heterologous expression of the tyrosine ammonia lyase coding gene (talFjCg) derived from the flavobacterium genus makes it possible to convert endogenous tyrosine into p-coumaric acid (p-CA1).

2. By blocking the key reaction of phenylpropane degradation pathway (knocking out the phd gene cluster), product consumption (p-CA2) was avoided.

3. Regulate the carbon sulfur (pheAGTG, AroFS188C) entering the shikimic acid pathway (SA) and aromatic amino acid synthesis pathway, allowing more carbon to flow towards the SA pathway and synthesize p-CA (p-CA3).

4. Reduce the production of by-product o-aminobenzoate (TrpEP304S) to obtain strain p-CA4; Avoid secreting extracellular p-CA and inhaling it into the cell again (∆ phdA), and construct strain p-CA5.

5. Promote the utilization of shikimic acid (aroKATG), reduce its accumulation, and use it more for the synthesis of p-CA, thus constructing the strain p-CA6; Further increase the carbon flow of the shikimic acid pathway (IGR: aroF * EcCg) to obtain strain p-CA7; Reduce PEP synthesis of pyruvate (∆ pyk) to obtain the final strain p-CA8.

6. Adjust the content of inorganic phosphorus in the culture medium to use more carbon sources for the synthesis of p-CA instead of growth. In the final determined culture medium, the highest titer of coumarin acid reached 661 mg/L (4 mM).

5. Finally, the production strain p-CA8 was used for co cultivation with a pre modified Corynebacterium glutamicum that converts coumaric acid into polyphenolic resveratrol. Without any addition of coumarin acid, the co cultivation of the two can utilize glucose to synthesize 31.2 mg/L (0.14 mM) of resveratrol.

Biosynthesis of p-coumaric acid from glucose via the shikimate pathway in C. glutamicum

Summary:

This study utilized heterotyrosine ammonia lyase combined with shikimic acid pathway optimization to achieve efficient production of p-coumaric acid using Corynebacterium glutamicum. This article uses a co culture mode to provide ideas for the synthesis of more plant natural products based on p-coumaric acid as a prerequisite.

Recommended Services and Products

|

Synthetic Biology PlatformCD Biosynsis offers a wide range of enabling technologies and a comprehensive synthetic biology toolbox to help our customers accelerate the design and construction of new biological entities or the re-design of natural biological processes through the iterative Design-Build-Test-Learn (DBTL) cycles of synthetic biology. |