1) Introduction to L-malic acid

Malic acid, also known as 2-hydroxysuccinic acid, has an asymmetric carbon hydroxysuccinic acid in its molecule, which has two stereoisomers and exists in three forms: L-malic acid, DL malic acid, and D-malic acid. It can be widely used in fields such as food and beverage, medicine, and chemical industry. Currently, the malic acid sold in the market is mostly L-malic acid and DL malic acid.

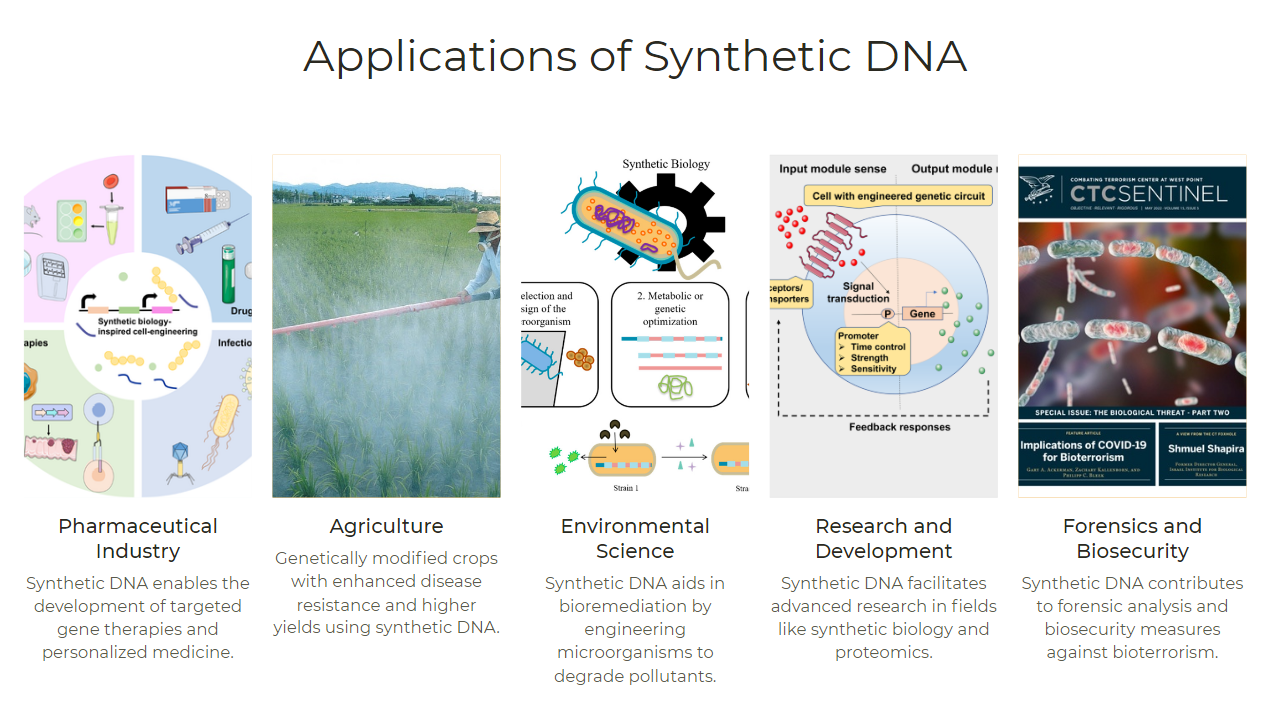

Fig1 Introduction to L-malic acid

L-malic acid is a natural organic acid that is widely present in fruits and vegetables such as apples, hawthorn, grapes, etc. Its taste is closer to that of fruit juice and it has a natural aroma. While possessing higher acidity, L-malic acid has less irritation and a softer taste. By combining with citric acid, a more natural, coordinated, and full-bodied sour taste can be achieved.

L-malic acid has a taste similar to that of natural apples. Compared with citric acid, it has a high acidity, a soft taste, a long retention time, does not damage teeth and oral cavity, and is beneficial for amino acid absorption and does not accumulate fat in physiological metabolism. It is a new generation of food acidity agents and is hailed as the “most ideal food acidity agent” by the biological and nutritional sectors. It is currently one of the largest and promising organic acids in the world’s food industry.

In terms of acidity, citric acid is currently the mainstream used in the domestic market, mainly serving as an acidity regulator in food and beverages. The taste of malic acid is different from that of citric acid. The acidity of citric acid quickly reaches its peak and decreases quickly, while malic acid stimulates slowly and its irritation can be retained for a long time.

The two flavors are also different, with malic acid having a sour taste about 20% stronger than citric acid. With the increasing understanding of domestic consumers about acid flavoring agents, the combination of malic acid and citric acid is currently used in many food and beverage products to simulate the sour taste of natural fruits, making the taste natural, coordinated, and full. The use of malic acid combined with citric acid as an acid flavoring regulator has gradually been favored by consumers.

According to data released by IMARC Services Private Limited, the global market size for citric acid in 2021 was approximately 2.7 million tons. Given the huge market size of citric acid, and the potential for the combination of malic acid and citric acid to replace citric acid to some extent, malic acid is expected to have a huge increase in demand.

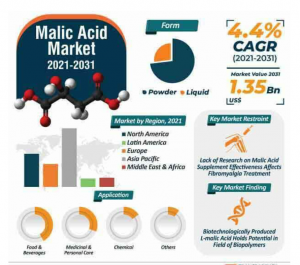

According to Transparencymarket research, the global malic acid market will reach 1.35 billion US dollars by 2031.

Fig2 Market of L-malic acid

In terms of annual demand, global malic acid reaches 856700 tons, corresponding to a CAGR of 7.33%, so the L-malic acid market may exceed 43000 tons. With the further cost reduction and efficiency increase of synthetic biology technology, its L-malic acid may replace most of the DL malic acid market, forming a dominant position.

Main players: Fuso Chemical, Bartek, Isegen, Polynt, Thirumalai Chemicals, Yongsan Chemicals, Tate&Lyle

If the construction of metabolic pathway design strains involves a fission process from 0 to 1 and industrialization from 1 to 100, a synthetic biology company must have talents with strong industrialization backgrounds; Construction, fermentation, purification, amplification, environmental protection, equipment, regulations, and other fields should all be understood, so that the design of the process will be comprehensively considered.

The development of L-malic acid biosynthesis projects is a combination of goal oriented and problem oriented approaches

Path design is the foundation (foundation) – production (surface)

Genetic modification is decoration (icing on the cake) – yield (points)

Fermentation regulation is a challenge (complex metabolism) – yield and quality

Purification process is key (impurities) – yield and quality

Synthesis (if any) process is key (stability) – stability and yield

Impurity research is a challenge (similar substances) – Quality (guiding regulation)

The analysis method is a tool (eye) ——- impurity research

Establishing a systematic and standardized research process that comprehensively considers various issues is beneficial for improving the efficiency of synthetic biology project development.

However, while the design may be simple, the melting temperature (Tm) cannot be fine tuned.