Spider silk is a strong animal fiber derived from spiders and can be used to make bulletproof vests. For decades, materials scientists have regarded spider silk as an environmentally friendly alternative to synthetic fibers such as nylon and Kevlar fibers, which are currently used in bulletproof clothing manufacturing. However, it is costly and requires a large amount of spider breeding.

The whole genome sequencing of Nephila clavipes shows that the spider silk protein in them is formed by three amino acid repeat units of glycine glycine and glutamine or alanine or tyrosine β- Layered structure, and β- The hydrogen bonds and other non covalent interactions before the layer allow the fibers to change shape during stretching without affecting the overall structure, ensuring durability and tensile strength exceeding that of Kevlar fibers.

Recently, AMSilk from Munich, Germany collaborated with 21st Bio to identify key fibrin sequences using artificial intelligence and machine learning, and express them in yeast cells and Escherichia coli. This synthetic spider silk not only has better mechanical strength than spider silk, but also does not activate the human immune system, and has a series of characteristics such as biocompatibility and biodegradability. Novo Holdings has invested 29 million euros in this synthetic biology platform, believing that they can adjust their genetic structure to produce fibers of different lengths and adapt to different applications. But for most fermented products, expanding production scale remains a challenge, as high production costs have led AMSilk, like many other spider silk companies, to choose to collaborate with partners such as Mercedes Benz and Adidas.

AMSilk’s main product, called Biosteel, is a biodegradable coating that can be used in medicine and cosmetics, and also used in sports shoes in cooperation with Adidas. The company has obtained several patents for protein polymer identification and fermentation, transforming synthetic fibers into environmentally friendly hydrogel or powder coatings.

Seevis Material Sciences, headquartered in Jerusalem, also uses yeast to produce spider silk fibroin. They use a patented self-assembly process, where protein monomers spontaneously assemble into larger SVX fibers (approximately 470000 monomers). Recently, the company has produced Spheroseev and Hydroseev fibers to provide scaffolds for cancer and stem cells, making them easier to detect under a microscope.

Natural spider silk has a protective stratum corneum outside, which is the key to its mechanical properties. However, the current artificial silk has a short mechanical maintenance time, which is a challenge for commercial production.Designing more genetically modified spiders containing valine, leucine, histidine, and arginine has resulted in stronger tensile strength and toughness than the silk of the Darwin bark spider (the strongest silk record), giving it the potential for commercialization.

Related recommendations

Strain Engineering for Spider Silk Protein

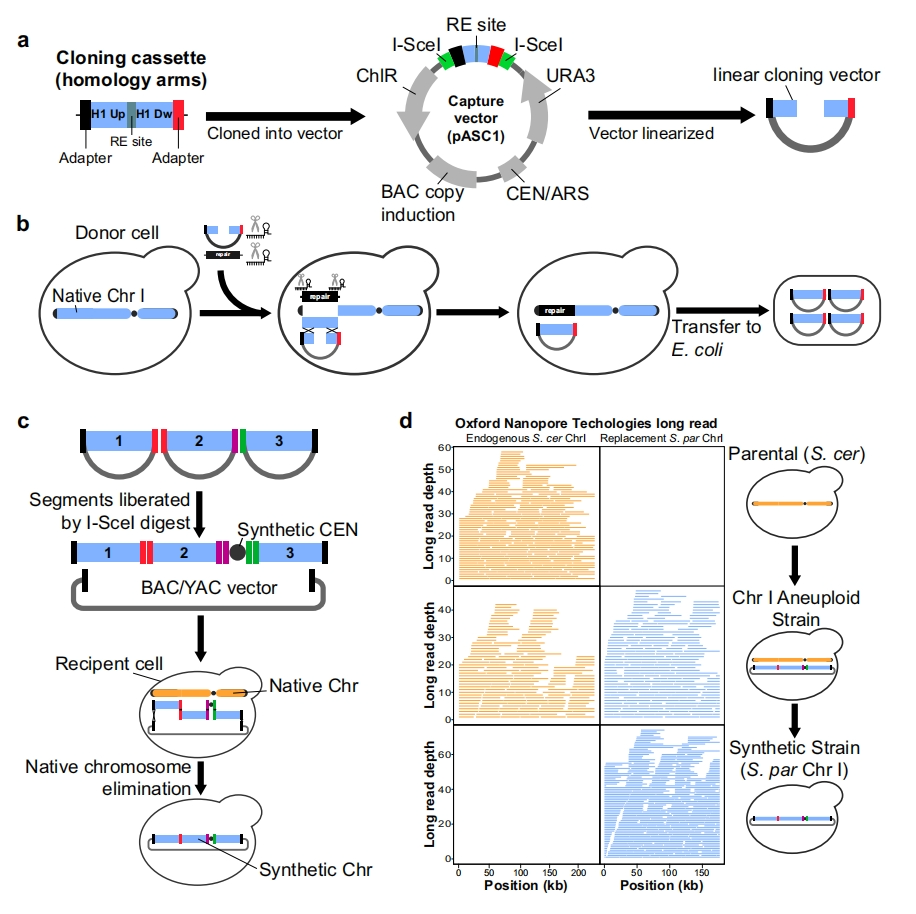

Genome Design

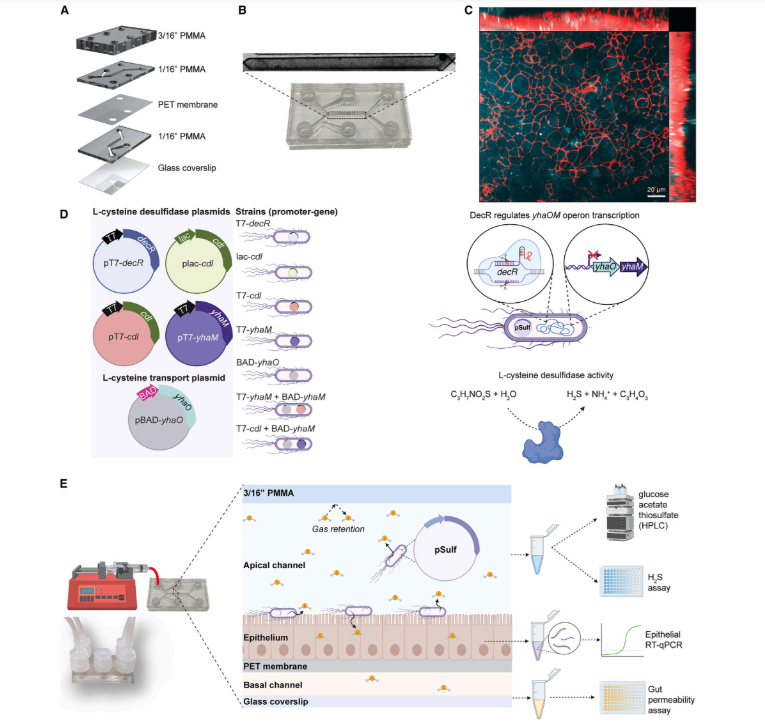

Genetic Circuit Design

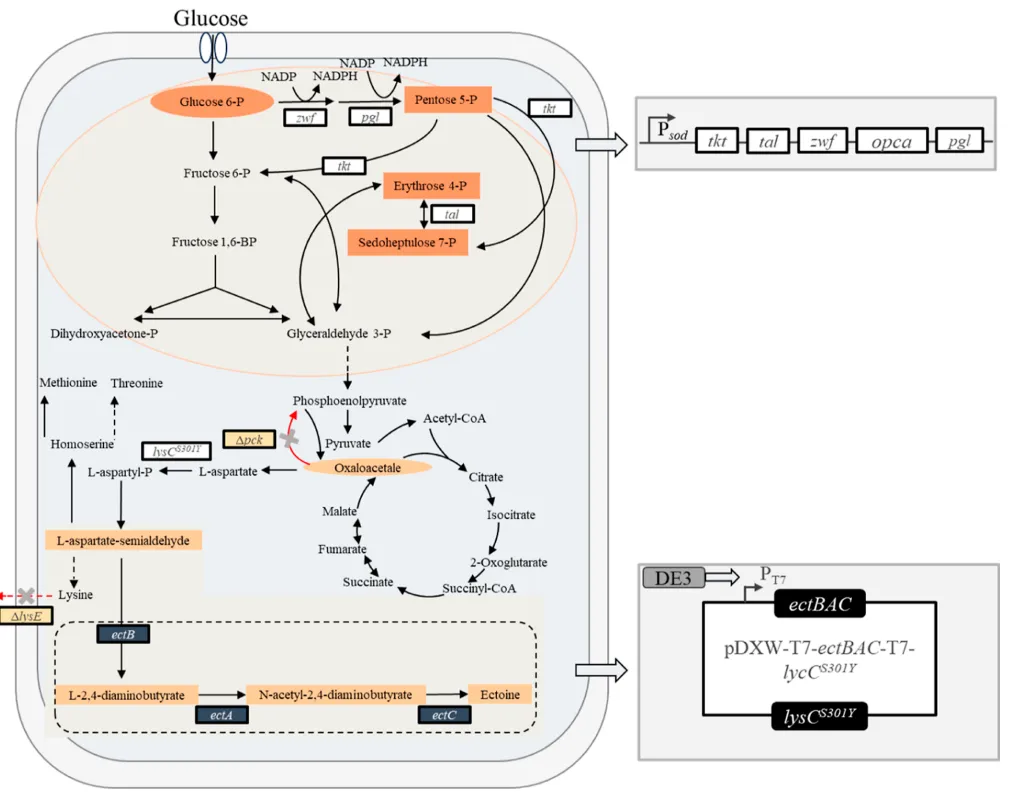

Pathway Design

Yeast Strain Modification

Yeast Cell Surface Engineering

Pichia pastoris Glycoengineering