Many microorganisms accumulate compatible solutes to counteract external pressures such as high osmotic pressure, high temperature, drying, and freezing. Among numerous compatible solutes, tetrahydropyrimidine stands out for its significant efficacy in effectively protecting halophilic cells from osmotic pressure imbalance and maintaining the stability of intracellular biomolecules.

Recent studies have shown that tetrahydropyrimidine has the potential for whitening, moisturizing, antioxidant, anti-aging, and UV radiation protection when applied to human skin; Tetrahydropyrimidine can also be used to treat inflammatory diseases such as allergic rhinitis, nasal conjunctivitis, tracheitis, and pulmonary inflammation. These high-value applications have resulted in a current selling price of approximately $1000 per kilogram, and have also contributed to the development of production methods.

At present, the production of tetrahydropyrimidine through microbial fermentation has been promoted to a large scale, and various fermentation strategies have been developed to increase yield, reduce production costs, and simplify production processes.

Related Services

E. coli CRISPR-Cas9 genome editing

E.coli Metabolic Engineering Service

Protein expression in E. coli service

In industry, the biosynthetic pathway of tetrahydropyrimidine has been clearly elucidated in H. elongata. In recent decades, low salt fermentation of tetrahydropyrimidine has been achieved in Escherichia coli, Corynebacterium glutamicum, brewing yeast, and Bacillus subtilis. In previous studies, based on engineered Escherichia coli, 25.1 g/L tetrahydropyrimidine was obtained with a productivity of 0.84 g/L/h.

(Source: ACS Synthesis. Biol.)

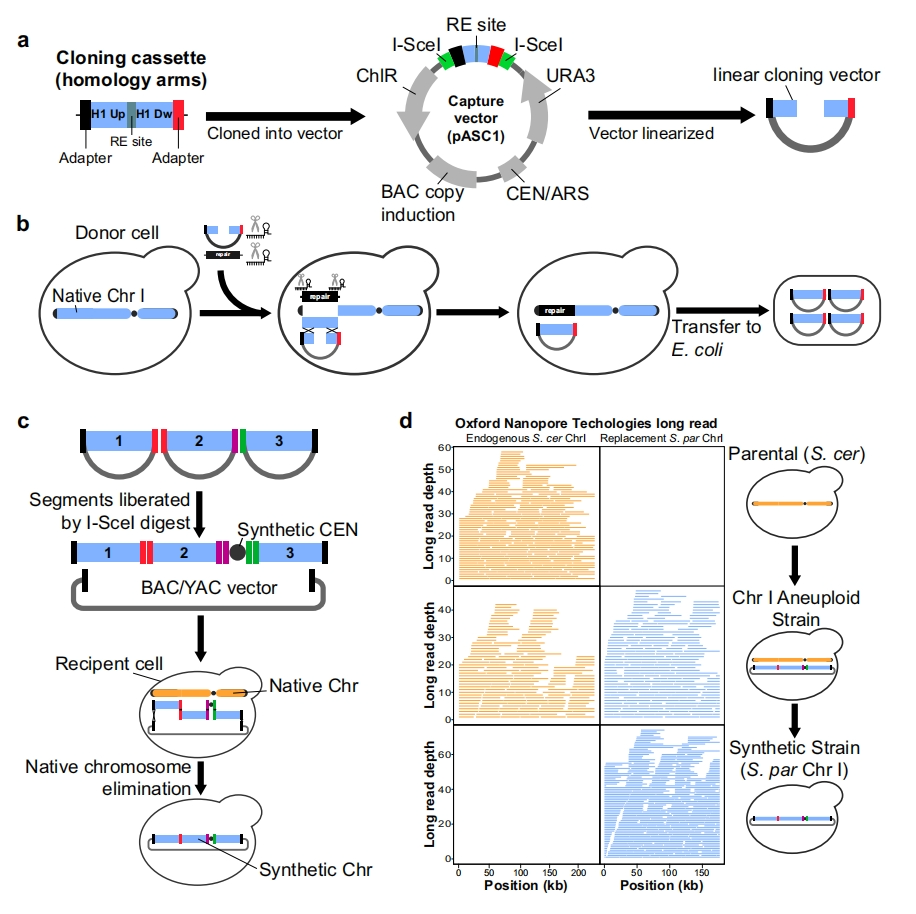

Recently, at ACS Synth A study titled “Metabolic Engineering of Corynebacterium glutamate for High Efficient Production of Ectoine” was published in Biol. The study involved heterologous expression of the tetrahydropyrimidine biosynthesis operator ctBAC gene from Streptomonas elongata, modification of Corynebacterium glutamate to produce tetrahydropyrimidine, and genetic modification, including the introduction of the de3 gene from Escherichia coli BL21 (DE3) to express the T7 promoter, elimination of the lysine transporter lysE to limit lysine production, and targeted mutation of lysine kinase lysCS301Y to alleviate lysine production. Feedback suppression. The engineering strain Ect10 obtained a tetrahydropyrimidine titer of 115.87 g/L in optimized feed batch fermentation, representing the highest tetrahydropyrimidine production level in Corynebacterium glutamicum, achieving efficient production of tetrahydropyrimidine in low salt environments.

Corynebacterium glutamicum is a type of Gram positive bacteria with high CG content, and is a major producer in the global amino acid fermentation industry. Due to the common precursor L-aspartic acid semialdehyde between L-lysine and tetrahydropyrimidine, the lysine producing strain of Corynebacterium glutamicum is considered the optimal host for tetrahydropyrimidine production. In recent studies, based on the engineering strain C. glutamicum ectABCopt, the production of tetrahydropyrimidine during feed fermentation was 65 g/L and 1.16 g/L/h.

Due to the industrial importance of Corynebacterium glutamicum, there is an urgent need for efficient and stable genome editing systems. The CRISPR-Cpf1 system has significant advantages in gene editing of Corynebacterium glutamicum. The system consists of FNCpfl, CRISPR RNA, and homologous arms, which can achieve gene editing with only one round of homologous recombination, greatly reducing time and workload.

This process also involves FNCpf1 cutting target DNA at specific sequences to produce sticky ends, thereby promoting gene deletion and insertion through homologous recombination. Subsequently, the temperature sensitivity of the plasmid was utilized to eliminate itself, resulting in the production of transgenic strains.

For the design of the ctBAC expression system. This study selected the ectBAC gene cluster from the original tetrahydropyrimidine producing strain H. elongata. The regulation of T7 promoter effectively decouples the expression of ectBAC operon from high osmotic pressure signals. Insert the T7 ectBAC cluster into the plasmid pDXW-10 and construct the plasmid pDXW-T7 ectBAC for synthesizing tetrahydropyrimidine in Corynebacterium glutamicum.

In order to achieve effective expression of the ctBAC gene cluster, the de3 gene from Escherichia coli BL21 (DE3) was inserted into the genome of Corynebacterium glutamicum ATCC13032 using plasmid pJYS3-de3, and the synthesis of tetrahydropyrimidine by Corynebacterium glutamicum was successfully achieved.

The next step is to carry out chassis design to further increase the production of tetrahydropyrimidine. To increase the synthesis flux of tetrahydropyrimidine and improve the availability of precursors and redox cofactors, the aspartic acid family synthesis pathway can be regulated by knocking down, weakening, or releasing feedback inhibition.

The construction strategy applied to high L-lysine producing strains can be applied to glutamate producing Corynebacterium strains, which may release higher tetrahydropyrimidine titers. According to previous research, reducing the extracellular transport of lysine by deleting the lysine transporter (LysE) can effectively reduce the accumulation of lysine in the fermentation broth.

High concentrations of intracellular lysine can inhibit the activity of aspartate kinase, which is a rate limiting enzyme of the amino acid aspartate family. In order to eliminate the feedback inhibition of lysine on aspartic kinase, researchers mutated serine at the 301 site of aspartic kinase to tyrosine according to literature reports.

picture

▲ Figure | Tetrahydropyrimidine biosynthesis pathway (source: ACS Synthesis. Biol.)

According to reports, deleting the PCK gene encoding phosphoenolpyruvate carboxyl kinase and replacing the natural promoter of TKT operon with a SOD promoter can increase the production of L-lysine, as the carbon flow towards oxaloacetic acid increases. This method may provide more precursors for the synthesis of tetrahydropyrimidine; In addition, in response to promoter replacement, the supply of NADPH is further increased by increasing the expression of genes involved in the pentose phosphate pathway.

This study cloned the ectBAC gene cluster of H. elongata into vector pDXW and transformed them into strains Ect01, Ect02, Ect03, Ect04, and Ect05, respectively. In a fermentation medium containing 100 g/L glucose, the highest tetrahydropyrimidine titer observed using Ect05 was 4.84 ± 0.18 g/L. By comparison, it was found that the enhancement of NADPH supply has a positive impact on the synthesis of tetrahydropyrimidine.

In addition, overexpression of aspartate kinase effectively increased the production of tetrahydropyrimidine. The biosynthesis of tetrahydropyrimidine relies on a large amount of ASA.

Electroconversion of carrier pDXW-T7-ectBAC lysCS301Y to C. glutamicum (DE3)- Δ In lysE lysCS301Y, strain Ect10 is produced. As expected, tetrahydropyrimidine producers with PCK deficiency and TKT promoter replacement achieved higher titers.

The titer of tetrahydropyrimidine produced by Ect10 increased to 4.94 ± 0.26 g/L, higher than Ect05, indicating that overexpression of aspartate kinase promoted the conversion of L-aspartic acid to tetrahydropyrimidine compared to strains expressing only ectBAC.

In addition, researchers evaluated that the optimal culture temperature for strain Ect10 to produce tetrahydropyrimidine was 30 ° C. In the shake flask fermentation experiment, the glucose concentration in the fermentation medium was set to five different concentration gradients: 10 g/L, 50 g/L, 100 g/L, 150 g/L, and 200 g/L, while all other relevant conditions were kept constant. The results showed that the highest tetrahydropyrimidine production (5.09 ± 0.20 g/L) was achieved at a concentration of 100 g/L compared to other groups, possibly due to the balance between cell growth and tetrahydropyrimidine synthesis under these conditions.

Next, in order to evaluate the performance under industrial conditions, the engineered strain Ect10 of Glutamate Corynebacterium was cultured in a stirred tank bioreactor using a feed batch fermentation mode. After 78 hours of fermentation, the final titer of tetrahydropyrimidine reached 115.87 g/L, with a total volumetric productivity of 1.49 g/(L · h) and a yield of 0.19 g/g.

In summary, the glutamic acid rod-shaped bacteria strain developed in this study has shown the highest known tetrahydropyrimidine production titer to date. This innovative method has great potential for application in other strains based on glutamic acid rods in the future.