The accumulation of antibiotics in agricultural soils poses a potential threat to soil ecosystems and crop growth, ultimately posing a threat to human health. Tetracycline antibiotics (TCs), such as tetracycline (CTC), oxytetracycline (OTC), and tetracycline (TTC), are widely present in soil as antibacterial agents. Generally speaking, tetracycline is difficult to completely metabolize in the body, so most of it is excreted into the ecosystem through feces or urine. Residual TCs not only increase bacterial resistance, but also exacerbate the amplification of resistance genes.

Laccase based bioremediation (EC 1.10.3.2, LAC) is an environmentally friendly method for removing organic pollutants. LAC belongs to the copper oxidase family and catalyzes the oxidation of phenolic compounds. The catalytic core of LAC consists of two copper centers. The main electron acceptor is T1 copper. After receiving a single electron, T1 Cu transfers the electron to the T2/T3 trinuclear copper center (T2/T3 Cu), accompanied by O2 reduction to H2O. The redox potential difference is an electrochemical driving force for electron transfer and plays a crucial role in the oxidation efficiency of LAC. Due to its wide substrate specificity, LACs have been applied in the bioremediation of TCs, dyes, pesticides, polycyclic aromatic hydrocarbons, and endocrine disruptors. However, due to the relatively low redox potential of LAC (0.4-0.8 V), LAC cannot oxidize substrates with high redox potential, which hinders its application.

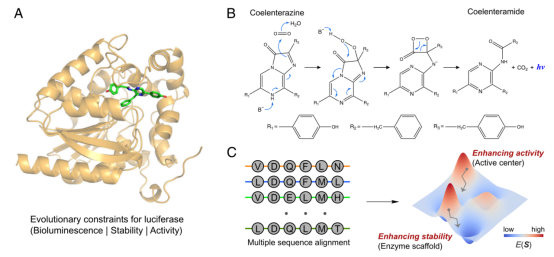

Some low molecular weight phenolic compounds are called mediators, which assist in the oxidation of LAC by generating active free radicals, and are considered a key factor in improving the oxidation efficiency of LAC. The LAC mediator system has great potential in the field of bioremediation, but its application is limited due to the high cost of LAC and mediators. This experiment developed a novel self amplifying catalytic system (SACS) that utilizes inexpensive lignocellulose to address the aforementioned challenges. SACS is a natural mediator regeneration system (Nm Re LAC) with high activity of LAC, prepared through solid-state fermentation of rice straw using a fungal combination (CtrAT) composed of T. reesei zJ09, Aspergillus niger, and T. versicolor. SACS can be established through three steps (Figure 1). Firstly, Nm Re LAC initiates the biodegradation of CTC, forming a CTC derived degradation intermediate (CTC327), which is identified as the active mediator of LAC. Subsequently, the interaction between CTC327 and LAC initiated a chain reaction for efficient conversion of CTC. In addition to antibiotic repair, SACS can also secrete multiple lignocellulosic degrading enzymes simultaneously, thereby achieving synergistic degradation of lignocellulose. In addition, the author also measured the biodegradation performance of SACS on total suspended particulate matter in soil and agricultural waste through a coupling process. This work provides an efficient and low-cost catalytic system for the remediation of organic pollutants and the degradation of lignocellulosic biomass.

01 Study on Nm Re LAC Mediated Antibiotic Degradation

Lignin has a complex structure and high rigidity, which affects the effective release of redox mediators. Trichoderma reesei ZJ09 can produce a series of lignocellulosic degrading enzymes (i.e. cellulase, xylanase, and LAC) and has significant catalytic activity on lignocellulosic biomass. However, the current strain has two drawbacks. Firstly, it is currently insufficient to achieve efficient oxidation of lignin. Secondly, in the cellulase complex produced by Trichoderma reesei ZJ09 β- The activity of glucosidase (BGA) is extremely low, leading to inhibition of the final product of cellulase.

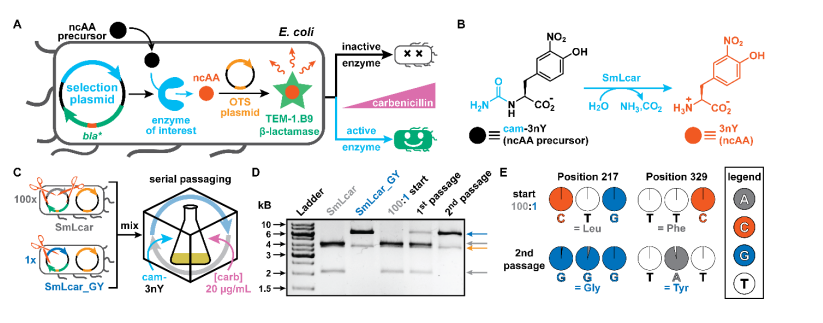

In order to construct a LAC natural mediator system for the degradation of tetracycline antibiotics, the author first developed a fungal combination (named CTrAT) that can effectively degrade straw. Subsequently, the highly active LAC and various phenolic derivatives generated by CTrAT degradation of straw were used to remove antibiotics. As shown in Figure 2a, the introduction of Aspergillus niger enhanced the BGA and endoglucanase activity (CMCase) of Trichoderma reesei ZJ09 and Aspergillus niger (T-An), with BGA and CMCase activities reaching 25.49 and 1778.72 IU g-1, respectively, 18.6 and 1.47 times higher than Trichoderma reesei ZJ09 alone.

The enzyme production and straw degradation results of the CTrAT strain combination composed of three fungi (Trichoderma reesei ZJ09, Aspergillus niger, and Coriolus versicolor) indicate that the combination has good compatibility and can overcome the shortcomings of two co cultured strains. The cellulose degrading enzyme (FPA) and LAC activity produced by CTrAT showed rapid growth within the first 2 days. On the 10th day, the activities of LAC, FPA, xylanase, endoglucanase, CMCase, and BGA were 1.88, 2.25, 1.45, 1.54, and 20.10 times higher than those of Trichoderma reesei ZJ09 alone (Figure 2c). The rapid degradation of cellulose and hemicellulose by CTrAT occurs at the beginning of the SSF stage (0-4 days), and then the degradation rate slows down (Figure 2d). On the 8th day, the degradation of cellulose and hemicellulose accelerated again, with LAC activity exceeding 46.23 IU g-1 (Figure 2c), reaching 77.25% and 75.33% respectively on the 12th day. One explanation is that the secretion of LAC mediated by CTrAT improves the effective decomposition of lignin, subsequently making cellulose and hemicellulose more easily utilized by microorganisms.

During the effective degradation process of straw mediated by CTrAT, a natural mediator regeneration system (Nm Re LAC) with high LAC activity was formed, in which phenolic compounds released from lignin decomposition can serve as natural intermediates for LAC. After 4 hours of treatment, without adding any mediators, the degradation rate of Nm Re LAC mediated TCs reached 89.12% for OTC and 95.69% for CTC, which is equivalent to the LAC mediator system with additional mediators.

Phenolic substances can be converted into less toxic compounds after being treated with the LAC mediator system. In this study, four possible biodegradation intermediates for CTC treated with Nm Re LAC were identified, with measured masses (m/z) of 430.11406.09327.11 and 284.07 (Figure 3a), while the m/z of CTC was 480.13. These four conversion products are named CTC 430, CTC 406, CTC 327, and CTC 284. Based on four identified products, a mechanism for Nm Re LAC conversion into CTC was proposed (Figure 3b).

CTC first undergoes demethylation and dehydroxylation to generate CTC 430, and then the dimethylamino group at C4 position is double demethylated to generate CTC 406. Subsequently, after the C7 dechlorination (Cl) reaction, phenoxy radicals are generated and oxidized to the corresponding quinone (CTC284). This study identified new intermediates for CTC degradation, filling the gap in the mechanism of fungal degradation of CTC.

Figure 2

02 Self amplification catalytic system based on Nm Re LAC

In this study, two quinone compounds (CTC327 and CTC284) were produced through the degradation of CTC catalyzed by Nm Re LAC (Figure 3). Quinone compounds are suitable electron donors in the redox process, thereby improving the remediation efficiency of pollutants.

Figure 3

In order to elucidate the catalytic enhancement mechanism between LAC and quinone compounds, the author used molecular docking to study the interaction between LAC and the main CTC degradation products (CTC430, CTC406, CTC327, and CTC284), as well as typical artificial mediators (HBT) and natural mediators (butyraldehyde and vanillin) of the Pseudomonas aeruginosa (P. sanguineus). The affinity value of CTC327 and LAC in T1 Cu (one of the catalytic cores of LAC) is -6.4 kcal mol-1, while the affinity value of HBT and LAC is -4.8 kcal mol-1, indicating that the interaction between CTC327 and LAC can occur spontaneously. Compared with HBT, CTC327 has a relatively high affinity. In addition, compared to other mediators, CTC327 reduces the distance from T1 copper.

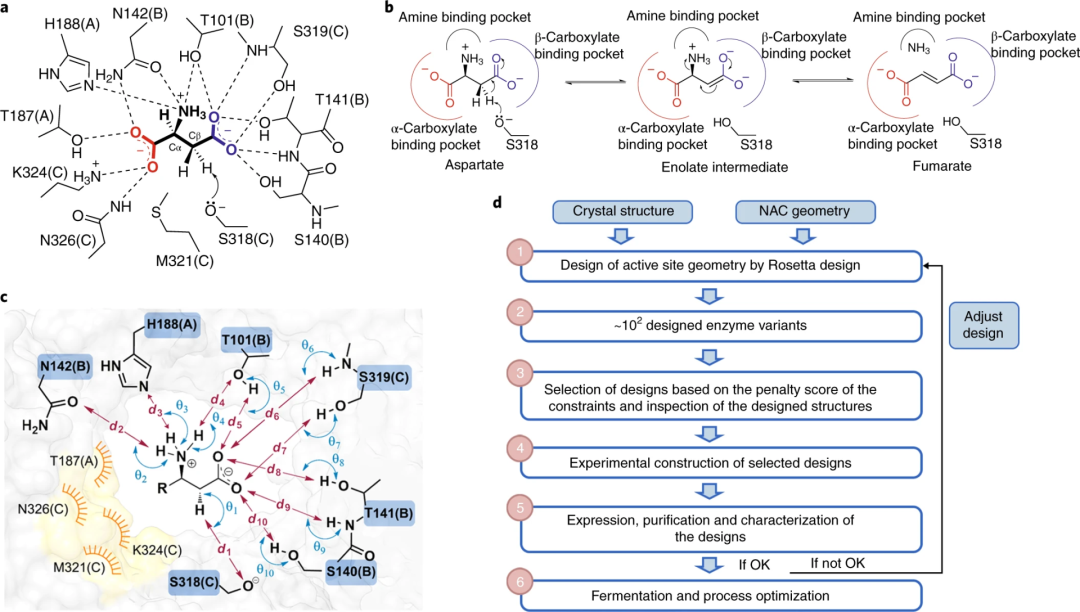

Therefore, the author established a three-step SACS (Figure 1). In SACS, after initial CTC degradation mediated by Nm Re LAC, the active mediator CTC327 is produced. Subsequently, the interaction between CTC327 and LAC can stimulate the degradation of CTC, thereby increasing the release of CTC327, resulting in a chain reaction of efficient CTC repair. By analyzing the interaction between LAC and CTC327, the mechanism of action of SACS is elucidated. In the LAC-CTC327 complex, CTC327 is surrounded by residues Pro412, Phe286, Phe353, Phe183, and Asp227 (Figure 4b). In the binding pocket of the LAC-CTC327 interaction system, the hydroxyl groups in Asp227 and CTC327 form a hydrogen bond at a distance of 3.63 Å. A π – π stacking interaction between the CTC327 parallel benzene ring and the Phe183 parallel benzene ring has been established. In addition to hydrogen bonding and π – π stacking interactions, hydrophobic interactions between the hydrophobic groups of LAC (Pro412, Phe286, Phe353, and Phe183) and the benzene ring of CTC327 were also observed (Figure 4b).

The RMSD diagram shows the stable interaction between LAC and CTC327 (Figure 4e). By Gmx_ The binding free energy of LAC-CTC327 calculated by the MMPBSA tool is -137.851 KJ mol-1, indicating its high stability. Asp228, Asp248, Ile250, Gln251, Pro278, Pro310, Pro313, Pro408, and Thr444 showed significant effects on the intermolecular interactions of LAC-CTC327, with Pro313 having the highest negative energy (Figure 4f). Based on the results of molecular docking analysis, a possible electron transfer pathway in the SACS mediated CTC oxidation process is proposed in Figure 4g. Firstly, an electron is transferred from CTC327 to T1 Cu of LAC, leading to the formation of phenoxy radicals (PhO ·). Afterwards, T1 Cu transfers electrons through the Cys Hiss pathway to a trinuclear cluster composed of T2 Cu and two T3 Cu atoms, where electrons are collected until four electrons are collected. Then T3 Cu atoms transfer electrons to T2 Cu, and O2 molecules reach the metal ion through an oxygen channel and reduce to H2O, accompanied by the formation of hydroxyl radicals. The unpaired electron delocalization of free radical intermediates will increase their chances of interacting with the O-H bond of CTC through the hydrogen extraction pathway, thereby stimulating the catalytic cycle and improving repair efficiency.

Figure 4

03 Catalytic performance of self amplifying catalytic system in bioremediation

Subsequently, the effects of five main factors, including temperature, soil moisture content, soil pH value, Nm Re LAC dosage, and Nm Re LAC usage form, on the degradation rate of CTC in soil were studied. As shown in Figure 5a, the degradation rate increases as the temperature increases from 15 ° C to 30 ° C. When the temperature reaches 35 ° C, the degradation rate significantly decreases due to a decrease in LAC activity and an increase in water loss. The optimal moisture content is between 40% and 50% (Figure 5a). Under higher moisture conditions, oxygen utilization is limited and CTC degradation rate decreases. The relative degradation rate remains above 80% within the range of pH2-5. The optimal pH value is 3.0 (Figure 5a). Meanwhile, the dose of Nm Re LAC can significantly promote the degradation of CTC, up to 0.15 g/g of soil, but further increase in dose has little contribution to the degradation rate (Figure 5a).

In order to simulate agricultural production practices, two models (synchronous model and segmented model) were used to study the ability of SACS coupling soil and straw to degrade CTC. The separation model refers to the placement of CTrAT inoculated straw on a plastic film shell to obtain Nm Re LAC; Sync mode refers to placing straw inoculated with CTR directly on CTC contaminated soil. After 10 days of cultivation, the Nm Re LACs obtained from the two models were mixed into the soil. As shown in Figure 5b, in the Sync model, due to the strong water holding capacity of the soil, the water content is maintained at ≈ 80%. In contrast, the moisture content of the separation model decreased to 70.74% on the 10th day. In addition, the LAC activity in the Sync model is higher than that in the separation model.

In order to analyze the soil remediation efficiency of the two models, the degradation rate of CTC at different soil depths was measured on the 10th and 16th days. As shown in Figure 5c, under the Sync model, in the first stage (0-10 days), the shallow soil depth of CTC can be repaired, reaching 85.92% and 55.36% at 0.5 and 1.5 cm on the 10th day, while the separation group and control group are less than 10% at this stage. After Nm Re LAC was added to the soil, the degradation rate of the second stage (10-16 days) separation group significantly increased, reaching 92.88%, 87.93%, and 93.01% at 0.5, 1.5, and 2.5 cm, respectively. On the 16th day, the Sync model still showed good remediation effect, with degradation rates of over 97% in all soil layers. In summary, the synchronous model has good water retention performance and enzyme production performance, thus exhibiting good remediation performance in the coupled degradation of CTC in soil and straw.

Figure 5

04 Coupling of CTC contaminated soil remediation and straw degradation

Water replenishment is crucial for straw degradation and soil remediation, as the combined process is carried out in the open air. The amount of water added may vary depending on the specific environmental temperature, as higher temperatures may increase the evaporation of moisture from straw and soil, and affect the water holding capacity of the straw substrate. Therefore, within the temperature range of 25-35 ° C, three levels of water addition (20%, 40%, and 80%) are applied daily. At a fixed temperature, supplementing water increased the moisture content of the straw substrate (Figure 5d). When the temperature is set at 25 ° C, the change in water replenishment does not result in a significant difference in substrate moisture content. This indicates that the water holding capacity of the straw substrate is close to its upper limit at this temperature, and further increase in daily water replenishment is difficult to improve the substrate moisture content.

In this study, at a fixed temperature, LAC activity was higher when the water content approached 75% (Figure 5d). The activity of LAC and cellulase are two key factors controlling straw degradation, therefore similar results can be observed in terms of straw biomass loss. As shown in Figure 5d, at a fixed temperature, when the moisture content of the straw approaches 75%, the biomass loss reaches its maximum value during the corresponding replenishment. But when the temperature rises to 35 ° C, the degradation of straw is inhibited, indicating that this temperature seriously affects the metabolism of straw combinations and the production capacity of enzymes.

At a certain temperature, the degradation rate of soil surface CTC increases with the increase of daily water addition. At a fixed daily water addition, the maximum CTC degradation rate is reached at 30 ° C, which is consistent with the optimal temperature for SACS catalyzed CTC removal (Figure 5a). The results showed that at 30 ° C, the appropriate combination of CTC and straw for daily water addition and temperature coupled degradation was 80%.

The coupling effect of straw degradation and bioremediation of CTC contaminated soil was studied using an improved coupling process. The changes in LAC activity, straw mass loss, and average CTC degradation rate during the coupling process are shown in Figure 5e. The Nm Re LAC produced in the first stage of the coupling process can secrete several enzymes, including LAC. LAC activity rapidly increased in the first 8 days and reached 46.7 IU g-1 on the 10th day. Nm Re LAC triggers CTC degradation and releases the active medium CTC327, thereby improving the catalytic ability of Nm Re LAC and promoting the conversion of CTC to CTC327, thus forming a self amplifying catalytic system. Therefore, in the second stage, when Nm Re Lac was mixed into the soil, rapid degradation of CTC was observed. On the 14th day, the average degradation rate of CTC reached 93.43%, and the loss of straw quality was 58.35% (Figure 5e).

For the first stage of CTC remediation at different soil depths, CTC degradation is mainly mediated by SACS and occurs at shallow soil depths. During this period, LAC began to infiltrate the soil with water and slowly degraded CTC at a depth of 0.5 cm on the 10th day, with a degradation rate of 85.78% (Figure 5f). However, due to the limited number of LAC entering the water through this pathway, the degradation rate of CTC significantly decreases with increasing soil depth, with a degradation rate of less than 10% on the 10th day at a soil depth of 2.5 cm. In the second stage, in addition to the completely mixed Nm Re lac, continuous evaporation may also lead to upward migration of pollutants. Therefore, on the 14th day, when the soil depth was 0.5, 1.5, and 2.5 cm, the degradation rate of CTC began to increase, reaching 94.39%, 93.48%, and 92.42%, respectively.

Related recommendations

Strain Engineering for Laccase

One-stop Enzyme Discovery and Design Services