Curcumin is a polyphenolic compound with good biological activity. It exists in the plant turmeric and has low water solubility. It has great potential as an antioxidant, anti-inflammatory, anti-cancer and anti diabetes drug. Therefore, curcumin is considered a safe and promising drug that can be used to prevent and treat various diseases. Curcumin is mainly extracted from plants, but due to the low content of curcumin in plants, the extraction process is costly, time-consuming, and environmentally unfriendly. The chemical synthesis of curcumin also involves multi-step reactions using toxic protectants. Therefore, the heterologous biosynthesis of curcumin is considered the most reliable method for obtaining a large amount of high-purity curcumin, and has been reported.

The metabolic engineering of improving curcumin biosynthesis in Escherichia coli has been published in the Journal of Agriculture and Food Chemistry. This blog mainly introduces this article

Related Services

1、 Materials and Methods

1.1 Strain and culture medium.

E. Molecular cloning of coli strain MC1061, strain BW25113 and its derivatives were used for the biosynthesis of curcumin, while LB and M9 media were prepared.

1.2 Plasmid construction.

See Table S1, Table S2, and Table S3 below.

picture

picture

picture

1.3 Strain construction.

Strain BW 25113 refers to E. coli BW25113. In order to increase the level of malonyl CoA, the fabF gene of this strain was knocked out and named CUR01. Simultaneously utilizing λ- Red recombination technology knocks out the curA gene in strain CUR 01 to reduce the degradation of curcumin. In order to eliminate the kanamycin resistance gene, the plasmid pCP20 was transformed into a selected strain with curA knockout. Ampicillin resistant transformants were selected at 30 degrees Celsius, followed by non-selective purification of a few colonies at 42 degrees Celsius. The loss of all antibiotic resistance was tested, and the resulting strain was named CUR02.

Construction of a 1.4CUS random mutation library.

A CUS random mutation library was constructed using error prone PCR. Primer pairs pYCA/pYCA Rev were used to amplify the cus gene, using plasmid pYCA as a template. The PCR reaction mixture consists of 5 mM MgCl2, dATP and dGTP each 0.2 mM, dCTP and dTTP each 1 mM, and 0.1 mM MnCl2 and rTaq DNA polymerase. Then, the PCR product containing the randomly mutated cus gene was used as a large primer, and the plasmid pYCA was used as a template for MEGAWHOP PCR 26. After MEGAWHOP PCR, perform template DpnI digestion (20 U) at 37 ° C for 12 hours. DpnI is inactivated at 80 degrees Celsius for 20 minutes. Convert the PCR product into E.coli MC 1061 and recover approximately 1 × 105 transformants. Sequencing was performed on 10 randomly selected clones from the library, each clone containing an average of 3 nucleotide mutations. Use all colonies from agar plates for plasmid extraction to prepare plasmid libraries.

Screening of 1.5CUS random mutation library.

Use a CUS random mutagenic library plasmid to transform strain CUR 02 and allow the transformed cells to grow on YM 9 agar plates supplemented with 1mM L-arabinose and 2 mM ferulic acid. After incubation at 30 ℃ for about 24 hours, select the yellowest clone representing the curcumin super producer (through the eyes) for re screening in a shake flask.

1.6 Production of curcumin in shaking bottles.

Inoculate the strains carrying biosynthetic pathways into a 100 mL shake flask containing 20 mL YM 9 medium, with an initial OD of 600 of 0.05. Cultivate at 37 ° C until OD 600 reaches 0.6, then add 1mM L-arabinose and 2 mM ferulic acid. When needed, add a certain amount of 0.4 mM isopropyl β- D-1-Thiopyranogalactoside (IPTG) induces gene expression under the control of the Ptrc promoter. If necessary, supplement with different concentrations of fatty acids, including stearic acid, palmitic acid, oleic acid, and palmitoleic acid. Then, further culture at 30 degrees Celsius for 12 hours.

1.7 Determination of Curcumin by High Performance Liquid Chromatography.

To 200 μ Add 800 to L culture medium μ L ethanol. After vortex and centrifugation, the supernatant was analyzed by high-performance liquid chromatography (HPLC) using the Shimadzu LC-20 A system (Shimadzu Corp., Japan). Mobile phase A is 0.1% formic acid, and B is acetonitrile. The linear gradient of mobile phase B (0-10 min, 20-45%; 10-20 min, 45-80%; 20-25 min, 80-100%) is used for separation at a flow rate of 0.8 mL/min. Injection volume of 10 μ L. Curcumin and ferulic acid were detected at 420 and 320 nm, respectively. Prepare standard curves using curcumin and ferulic acid standards to calculate concentration.

1.8 The protein expression was detected by sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE).

Inoculate the colony of strain CUR 02 carrying plasmids expressing CUS wild-type or mutant into 3 mL LB medium and incubate at 37 ° C until OD 600 reaches 0.6. Then, add 1 mM L-arabinose and further culture the cells at 30 ° C for 16 hours. Collect cells by centrifugation and resuspend in 10 mM PBS buffer (pH 7.4). Ultrasound treatment was performed using a JY 92-IIN ultrasonic cell crusher (Ningbo, China), followed by centrifugation and detection of CUS in soluble and insoluble phases after SDS-PAGE.

Purification and activity determination of 1.9 CUS.

The colony of strain BL 21 (DE 3) containing plasmid pET 28 a-CUS expressing CUS wild-type or mutant M1 was grown in 3 mL LB at 37 ° C for 12 hours. Then dilute the culture in 100 mL of the same medium to OD 600=0.05, and grow at 37 ° C until OD 600 reaches 0.6, then add 0.4 mM IPTG. Then, grow the culture continuously at 30 ° C for 16 hours. Harvest cells by centrifuging at 5000 g for 10 minutes at 4 ° C. Then resuspend the cells in 10 mL of 100 mM TrisHCl buffer and lyse them by ultrasound. Centrifuge the lysate at 10000 g for 10 minutes at 4 ° C. Apply the supernatant to Ni NTA resin (Sigma Aldrich). Wash the column with 100 mM Tris HCl buffer (pH 8.0300 mM NaCl, 20 mM imidazole) and elute the bound proteins with 100 mM Tris HCl buffer (pH 8.0300 mM NaCl, 250 mM imidazole). Remove imidazole by dialysis with 1OO mM potassium phosphate buffer (pH 8.0) at 4 ° C. The reaction mixture contains 1OO in 1OO mM potassium phosphate buffer (pH 8.0) μ M Feruloyl CoA, 1OO μ M malonyl CoA and 20 μ G purified enzyme. Incubate the reaction at 37 ° C for 1 hour and add 20 μ L 20% HCl terminated. Add equal volume of ethanol and mix, analyze the product using HPLC. The enzyme activity of one unit (U) is defined as the amount of enzyme required to produce 1 nmol of curcumin per hour.

1.10 Observe cell morphology through transmission electron microscopy.

Observe the cellular morphology of Almgs overexpression using transmission electron microscopy negative staining. Use plasmids pTrc 99a or pTrc 99a Almgs to transform strain CUR 02 and grow the transformed body at 30 ° C for 24 hours, induced by 0.4mM IPTG. Pick a single colony and resuspend it in a water droplet. Subtract the glow discharge copper grid from the water droplet for 1 minute, and use filter paper to discharge excess liquid. Wash the preparation quickly with distilled water once and stain with 0.05% uranyl acetate for 15 seconds. After air drying, observe the preparation using JEM-1400 TEM (JEOL, Japan).

1.11 Detection of membrane fluidity.

Detect cell membrane fluidity in the presence and absence of unsaturated fatty acids using 1,6-diphenyl-1,3,5-hexatriene (DPH) staining. In short, the single colony of strain CUR 02 carrying plasmid pYk CUS M1-4AT was cultured overnight in LB medium. Cells were harvested by centrifugation at 3000 g and suspended in PBS buffer. Subsequently, treat the suspension with 0.8g/L palmitic oleic acid at 30 ° C for 1 hour. Then, add 0.3mM curcumin and keep the sample at 30 ° C for another 2 hours. Centrifuge the sample, resuspend it in PBS buffer, and use 5 μ Μ DPH was stained in the dark at 37 ° C for 30 minutes. After washing twice with PBS buffer, analyze the relative fluorescence intensity of the sample using Synergy Mx Multi Mode Microplate Reader (BioTek, Vermont, USA) (350 nm excitation filter, 425 nm emission filter).

| Category | Subcategory | Product Name | Catalog Number | Price |

|---|---|---|---|---|

| Biosynthesis Chemicals | Anticancer Agents | Bisdemethoxycurcumin | BC-0523 | Online Inquiry |

| Biosynthesis Chemicals | Anticancer Agents | Demethoxycurcumin | BC-0553 | Online Inquiry |

| Biosynthesis Chemicals | Antioxidants | Curcumin, Curcuma longa (High Purity) | BC-0696 | Online Inquiry |

| Biosynthesis Chemicals | Antioxidants | Tetrahydrocurcumin | BC-0752 | Online Inquiry |

2、 Result

2.1 Construction of Curcumin biosynthesis pathway.

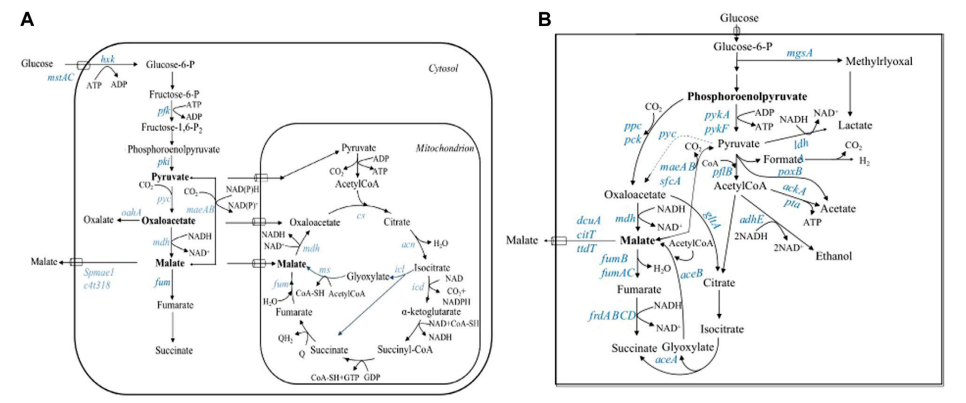

Curcumin is synthesized from ferulic acid through two steps catalyzed by 4-coumaryl CoA ligase (4CL) and CUS enzyme (Figure 1). Construct a curcumin biosynthesis pathway from O. sativa and 4CL mutant 4AT 21. Cultivate wild-type BW 25113 strain carrying plasmid pYCA under induction of biosynthetic pathway expression at 30 ° C for 12 hours and supplement with ferulic acid. Confirm the synthesis of curcumin and its presence in the culture medium using HPLC. A total of 0.015 mM curcumin was synthesized from 2 mM ferulic acid (Figure 2A).

2.2 Knockout of curA – reduces curcumin degradation.

Metabolic engineering strategies have been applied to improve intracellular levels of malonyl CoA and curcumin production. It was found that the inactivation of poxB, adhE, and fabF genes combined with overexpressed acs in strain CUR 01 can improve the biosynthesis of curcumin, as carbon flux effectively directs acetyl CoA, thereby directing malonyl CoA, and minimizing the flux of fatty acid biosynthesis. It has been reported that the gene curA encoding curcumin reductase is expressed in Escherichia coli. Therefore, the curA was knocked down to construct the strain CUR 02. Compare the curcumin production in the culture media of strains BW 25113, CUR 01, and CUR 02 carrying the curcumin biosynthesis pathway at 12, 24, and 36 hours after pathway induction. At 12 hours, the curcumin production in strain CUR 01 was 2.8 times higher than that in strain BW 25113, indicating that high intracellular levels of malonyl CoA were indeed beneficial for curcumin formation. In addition, strain CUR 02 has a curcumin yield 1.7 times higher than strain CUR 01, indicating a significant reduction in rapid curcumin degradation during production by knocking out curA (Figure 2A). Therefore, unless otherwise specified, the following studies were conducted in the CUR 02 strain.

2.3 Expression optimization of curcumin biosynthesis pathway.

In order to optimize the efficiency of biosynthesis, the curcumin biosynthesis pathway was expressed separately from plasmids with high (pACA), medium (pYCA), and low (pLCA) copy numbers under the control of the PBAD promoter in strain CUR02. It was found that strains carrying medium copy number plasmids produced the highest amount of curcumin. Then, the different sequences of the two pathway genes CUS and 4AT were compared, and the operon containing the cus gene upstream of the gene encoding the 4AT mutant produced a five fold higher curcumin production (Figure 2B). This indicates that higher levels of CUS expression are crucial for curcumin production.

2.4 Targeted evolution of CUS used to enhance curcumin formation.

We constructed a CUS random mutation library and performed high-throughput screening on agar plates. Based on the yellow color of curcumin, the darkest yellow colony was selected for shake flask re screening, and curcumin synthesis was determined by HPLC (Figure 3A, B). Two mutant strains producing higher levels of curcumin than those expressing wild-type CUS were obtained from a total of 1×105 screened variants. Mutant strains M1 and M8 showed curcumin production of 3.8 and 3.4 times, respectively (Figure 3C). Use SDSPAGE to study the expression levels of pathway enzymes in mutant and wild-type strains. The results showed that the expression levels of CUS M1 and M8 mutants were significantly higher than those of wild-type CUS, which helped to improve curcumin yield (Figure 3D). This once again proves that the biosynthetic efficiency of this pathway is limited by the steps catalyzed by CUS.

The sequencing results revealed amino acid substitutions in the CUS mutants Ml and M8 (Table 1), and the mutation A10 T was shared by both mutants. Purified the CUS wild-type and M1 mutant, and determined their specific activities to be 21.5 and 23.7 U/mg, respectively, indicating that the increase in the expression level of mutant M1 mainly helps to increase the yield of curcumin. Because all codon substitutions did not improve E. In Escherichia coli, the A10 T mutation is located in the translation initiation region, and NUPACK software packages were used to compare the mRNA secondary structures of wild-type and mutant enzymes. The minimum folding free energy of the 5 ‘region of the mRNA secondary structure of 33 wild-type and mutant enzymes is -14.49 kcal/mol and -9.44 kcal/mol, respectively. According to reports, the disruption of the stem ring structure encoding the first 14 amino acids led to an improvement in protein expression, indicating that the 5 ‘region of the mRNA secondary structure of wild-type enzymes may be too stable to provide relatively high levels of CUS expression.

2.5 Membrane engineering further increases the yield of curcumin.

The storage of hydrophobic compounds in the cell membrane is reliable. Therefore, increasing the content of hydrophobic compounds in the cell membrane can enhance the storage of curcumin in cells and improve its production. According to reports, Almgs induce the formation of numerous intracellular vesicles in Escherichia coli. In our study, TEM was used to observe that the strain CUR 02 overexpressing Almgs from plasmids pTrc 99a Almgs became larger in length and smaller in width compared to control cells that did not express Almgs (Figure 4A). Then, Almgs and curcumin co expressed plasmids pTrc 99a Almgs with two biosynthetic pathways in strain CUR 02 carrying plasmids pTrc 99a Almgs and pYk CUS M14 AT. The results showed that the yield of curcumin increased with the increase of Almgs expression level. Compared with the curcumin yield of the uninduced sample, the curcumin yield increased by 2.2 times when Almgs expression was induced with 0.4 mM IPTG (Figure 4B). Therefore, enhancing β- The membrane engineering strategy for the production of carotene and lycopene has also been proven to be beneficial for the production of curcumin.

2.6 Adding unsaturated fatty acids promotes the biosynthesis of curcumin.

In previous studies, the addition of unsaturated fatty acids improved the expression of recombinant brewing yeast β- The production of carotene is effectively absorbed by yeast cells and integrated into membrane lipids by unsaturated fatty acids. The effects of stearic acid, palmitic acid, oleic acid, or palmitoleic acid supplementation on curcumin biosynthesis were studied in strain CUR 02 carrying plasmid pYk CUS M1-4AT. The results indicate that different concentrations of stearic acid and palmitic acid are not conducive to the biosynthesis of curcumin. When the production of curcumin decreases, cells are treated with increased concentrations of stearic acid and palmitic acid, while cell growth remains unaffected. On the contrary, the addition of oleic acid and palmitoleic acid promotes the biosynthesis of curcumin (Figure 5A-D). In addition, supplementing the strain CUR 02 carrying plasmids pYk CUS M1-4AT and pTrc 99 a-Almgs with oleic acid or palmitoleic acid showed an additive effect on curcumin biosynthesis (Figure 5E, F). When producing curcumin in shake flasks with overexpression of Almgs and supplementation of 0.6g/L palmitoleic acid and 4 mM ferulic acid, 1.46mM curcumin was obtained within 48 hours (Figure 5G), which is close to the highest yield reported so far achieved within 63 hours.

2.7 The effect of membrane fluidity on the biosynthesis of curcumin.

The composition of membrane lipids, such as the ratio of saturated and unsaturated lipid acyl chains, is related to membrane fluidity. To monitor changes in membrane dynamics in the body, cells were incubated with the fluorescent marker DPH, which binds to membrane lipid acyls. If the membrane is damaged, the lipid dynamics are disrupted, and DPH cannot be inserted into the membrane. Therefore, the fluorescence intensity of DPH will decrease. Compared with untreated cells, cells treated with curcumin showed reduced DPH fluorescence, indicating that curcumin reduced the membrane fluidity of host cells. Treating cells with palmitic acid before curcumin treatment proved to restore membrane fluidity to some extent, making host cells more tolerant to curcumin (Figure 6). These results explain why the addition of unsaturated fatty acids leads to an improvement in curcumin production.

3、 Conclusion

In summary, this study optimized the rate limiting enzyme CUS for metabolic engineering of curcumin in E. coli BW 25113 strain and obtained enzyme mutants with significantly increased expression levels. In addition, this study also applied a novel metabolic engineering strategy – membrane engineering, to optimize the biosynthesis of curcumin. Overexpression of Almgs alters the morphology of cell membranes and enhances their curcumin storage capacity, thereby improving the biosynthesis of curcumin. The saturation rate of cell membrane fatty acids has also been engineered. It has been proven that unsaturated fatty acid supplements promote the biosynthesis of curcumin by enhancing cell membrane fluidity. It was found that these two membrane engineering strategies have cumulative effects on curcumin biosynthesis. Therefore, membrane engineering strategies can be used to optimize the biosynthesis of various hydrophobic compounds.